The AMPCO Standard of Technology

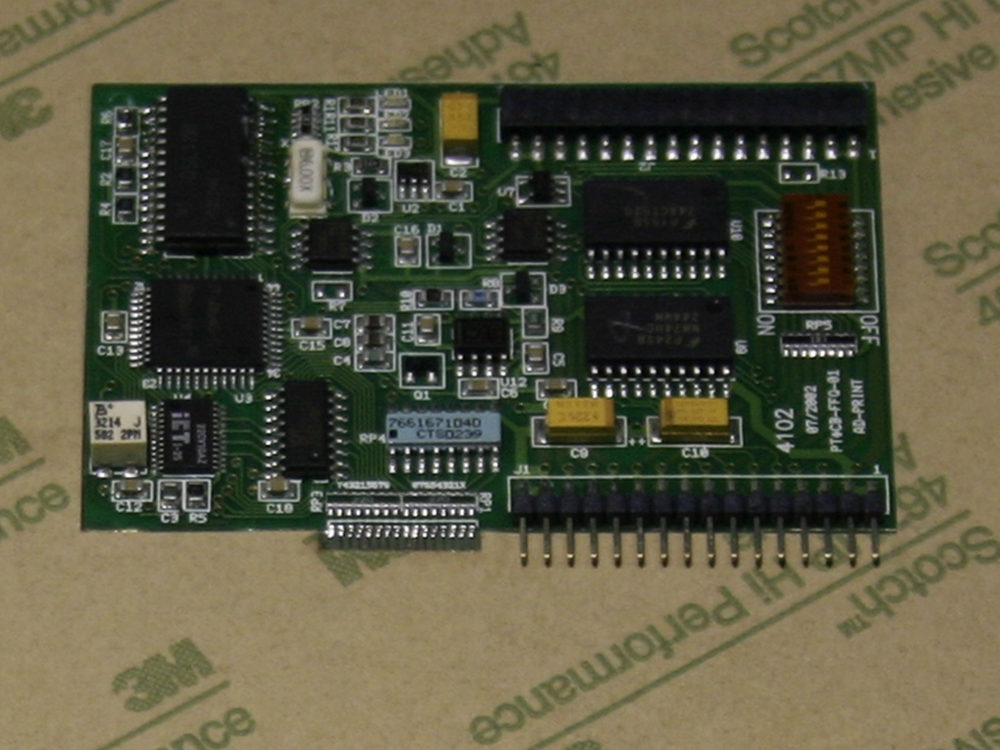

Ampco will take your PCBA design or design concept and help you create a high quality finished product that can consistently be manufactured in a wide range of volumes. AMPCO utilizes the latest available technologies in circuit board, user interface and product packaging design to minimize product cost and lead times while maintaining zero defect delivery and high filed reliability.

AMPCO utilizes three separate manufacturing locations to accommodate our customers electronic assembly needs in term of maximum annual volume and board complexity as follows:

Ampco Head Office:

- Prototype to medium volume

- Low to medium complexity

SAPA:

Strategic Advanced Product Assembly

- Prototype to high volume

- Low to high complexity

MTM Pacific

(Ampco Owned Subsidiary for

Asian Sourcing Requests):

- Prototype to high volume

- Low to very high complexity

OUR FACILITIES:

- ISO 14001, TS164949 certified

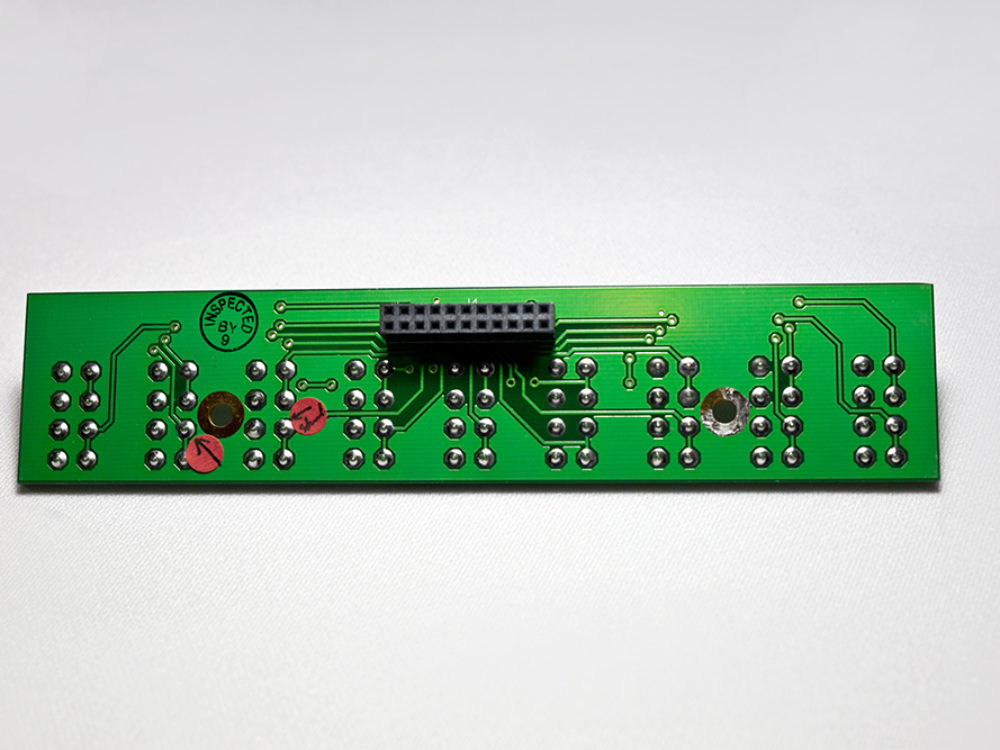

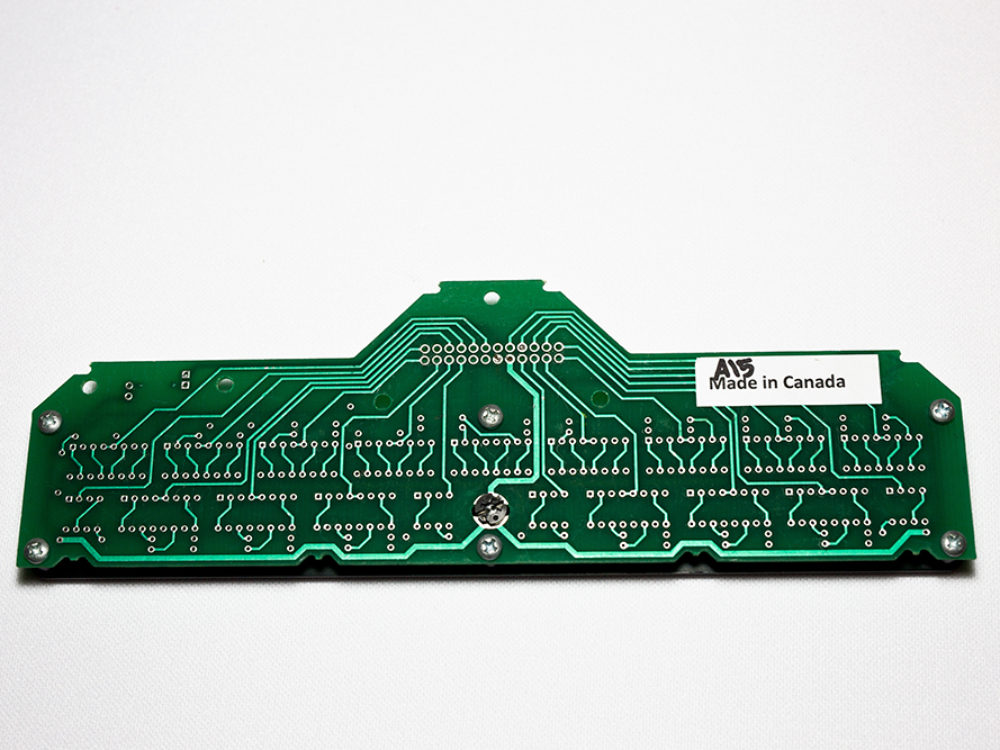

- SMT,THD,SMT/THD Mixed, Double Sided SMD/THD

- DIP, SOIC, PLCC, QFP, QFN, BGA, FBGA, VFBGA

- FR4 Flex, Rigid-Flex, membrane, no-clean, water wash, leaded/lead free (RoHS Compliance)

- X-Ray, AOI inspection

- Manual soldering for special temperature sensitive parts

- Electronic procurement, customer inventory management

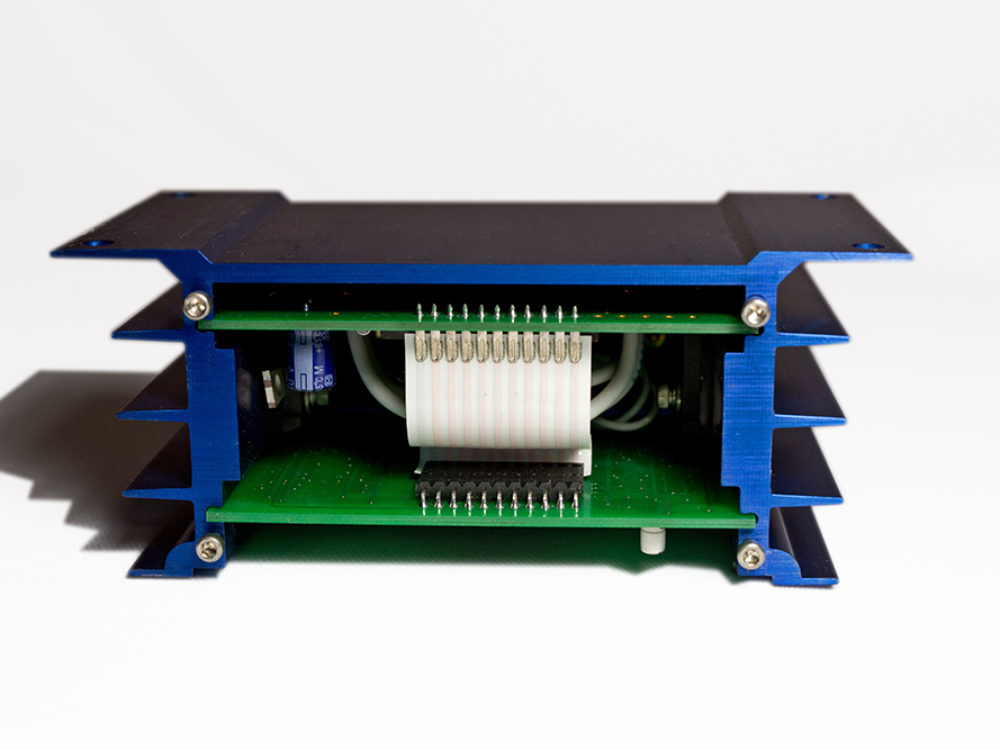

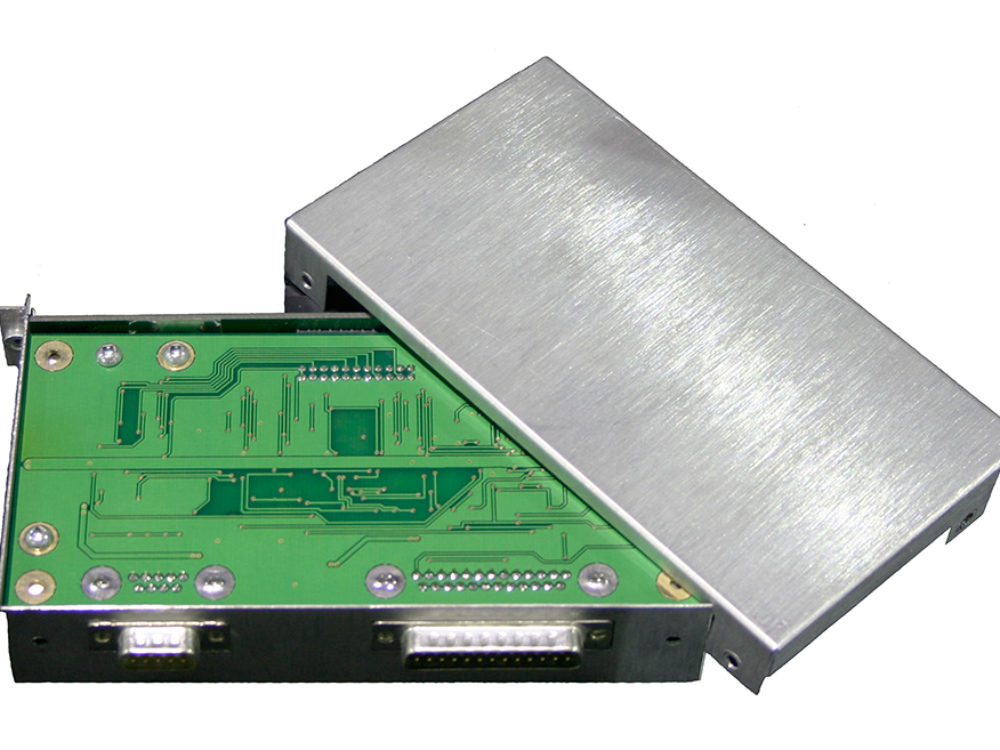

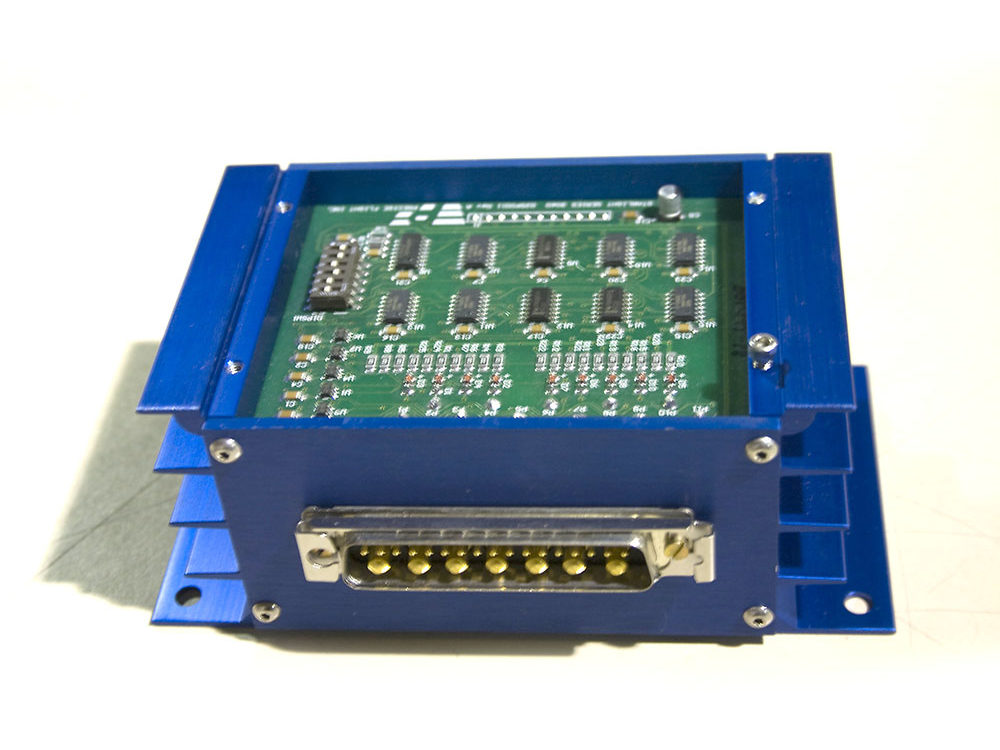

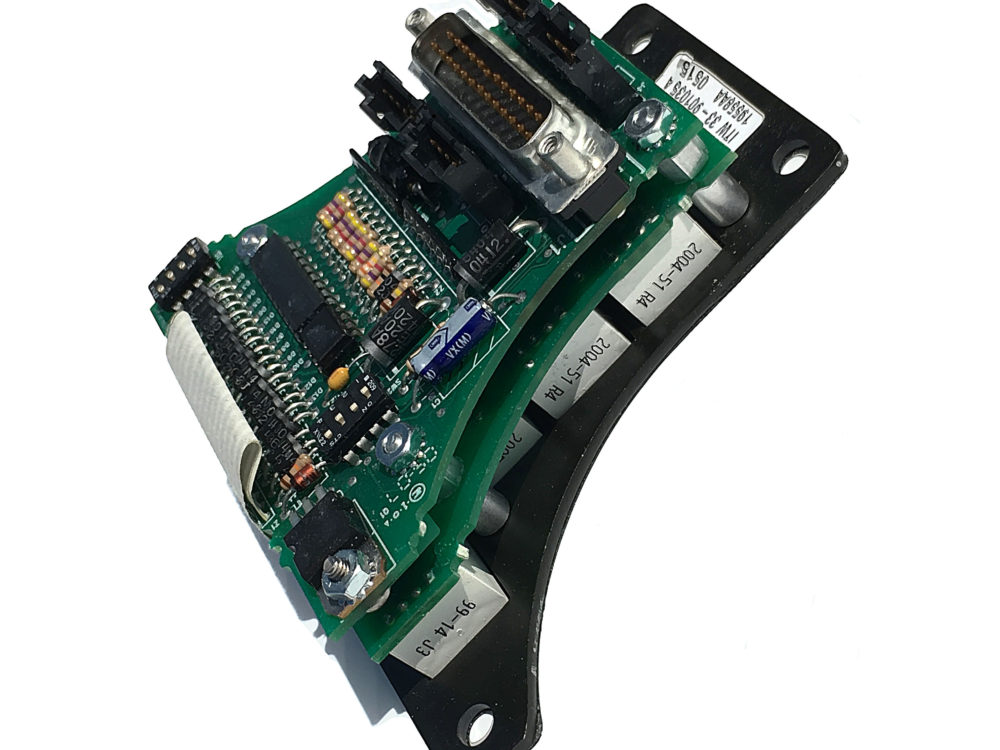

- Full mechanical assembly

- Full functional and final system test using customer or AMPCO designed test jigs, Flying probe, Bed of Nails active in-circuit

- Full ESD standards compliance, ESD shipping packaging

OUR INTEGRATED ASSEMBLY (BOX-BUILD) CAPABILITIES INCLUDE:

- PCBA + Enclosure + User Interface

- Membrane Switches, Molded Elastomeric Keypads / Switches

- Embedded Displays / Touch Displays

- Injection / Compression Molding

- Fabricated / Machined / Extruded Metal and Plastic

- Rubber Components

QUALITY AND SUSTAINABILITY:

- ISO 14001, TS16949:2009

- C-TPAT Certified

- G7 Colour Management Certified

- Six Sigma Process – Trained Black Belt on Staff

- 10 PPM Quality Standard