The AMPCO Standard of Technology

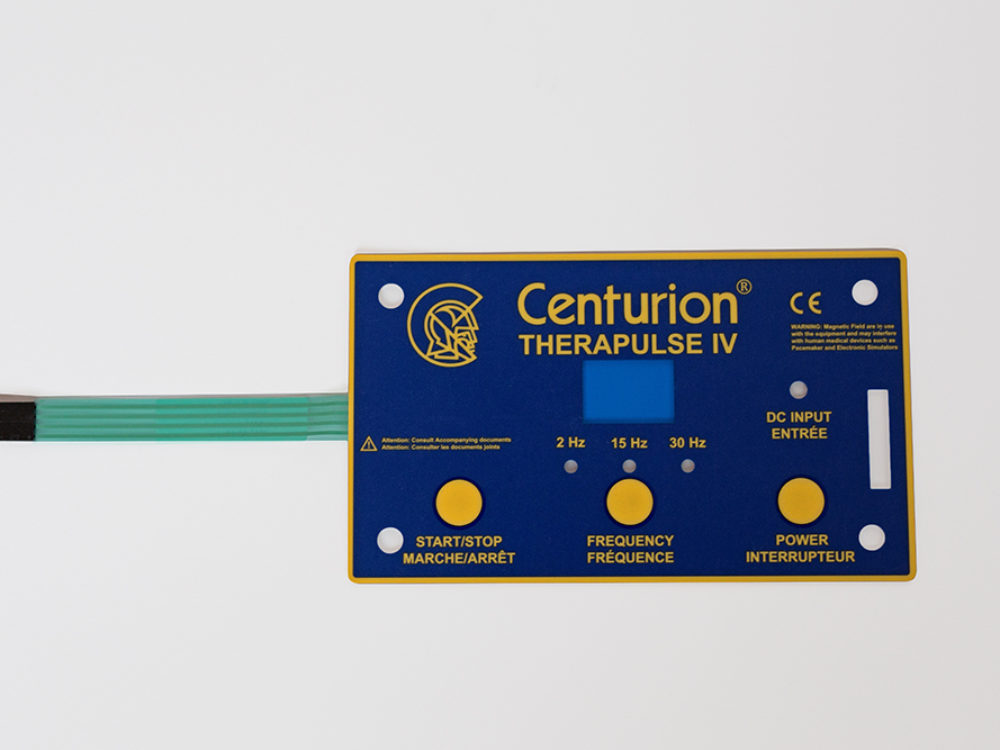

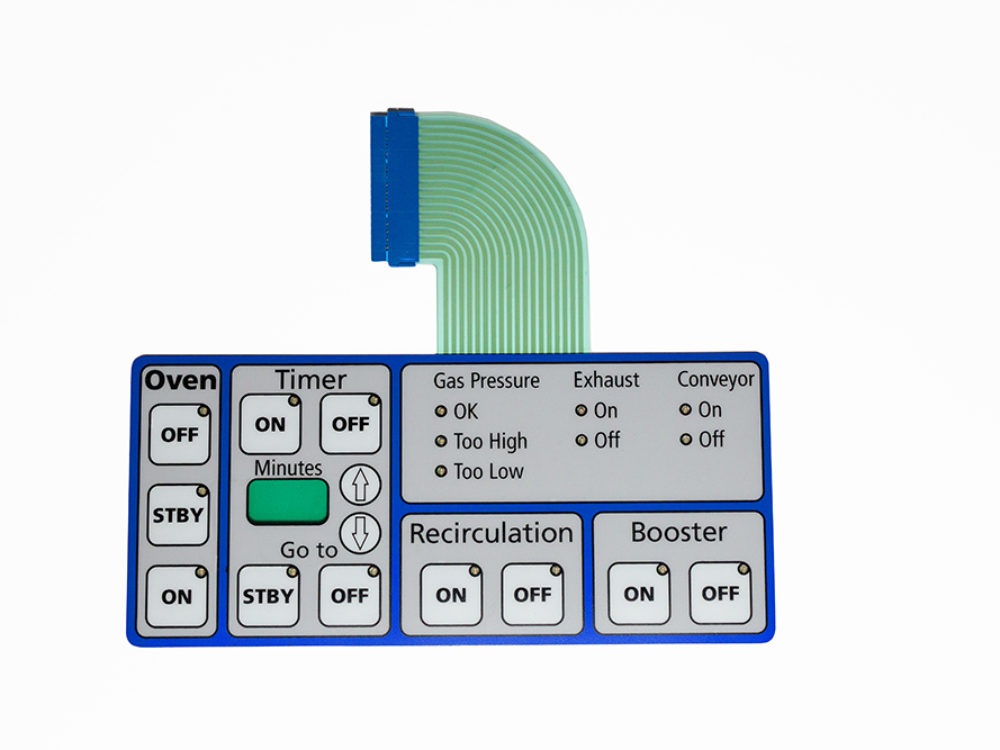

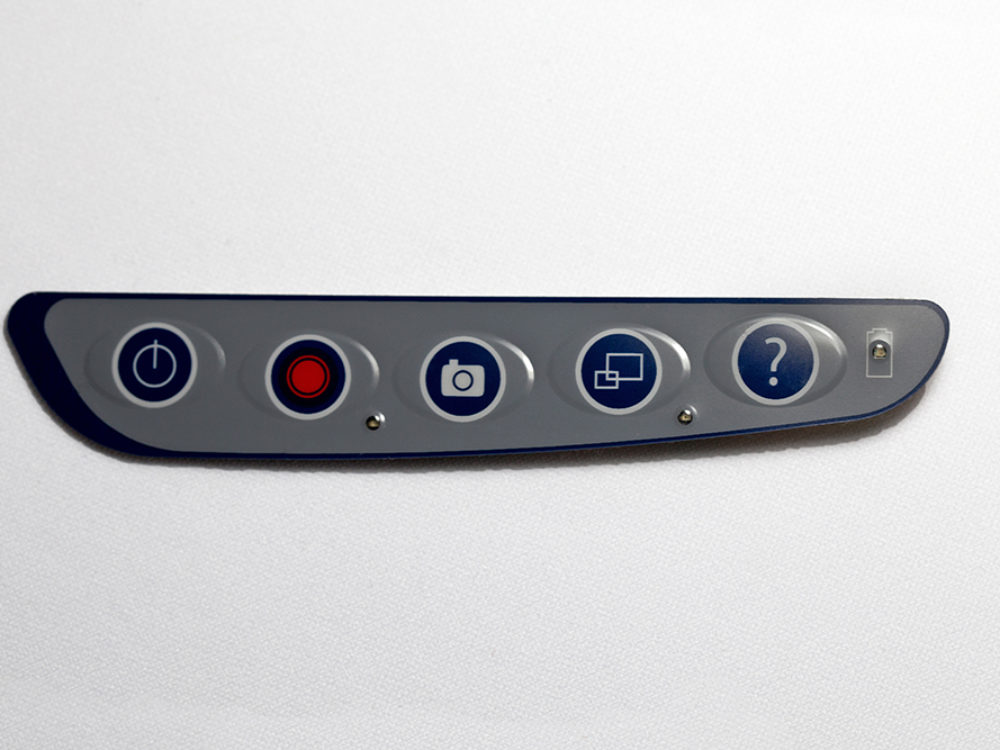

Membrane Switches and Interface Displays most often require versatile custom designs, low profile and simple installation. AMPCO’s custom Membrane Switches are the technology of choice for a wide variety of industrial commercial and consumer products. This includes portable electronics, diagnostic equipment and medical equipment.

We also integrate a wide variety of backlit technologies utilizing both flex and hardboard circuits. Combined with our graphic overlay and assembly capabilities AMPCO provides a full turnkey Membrane Switch solution.

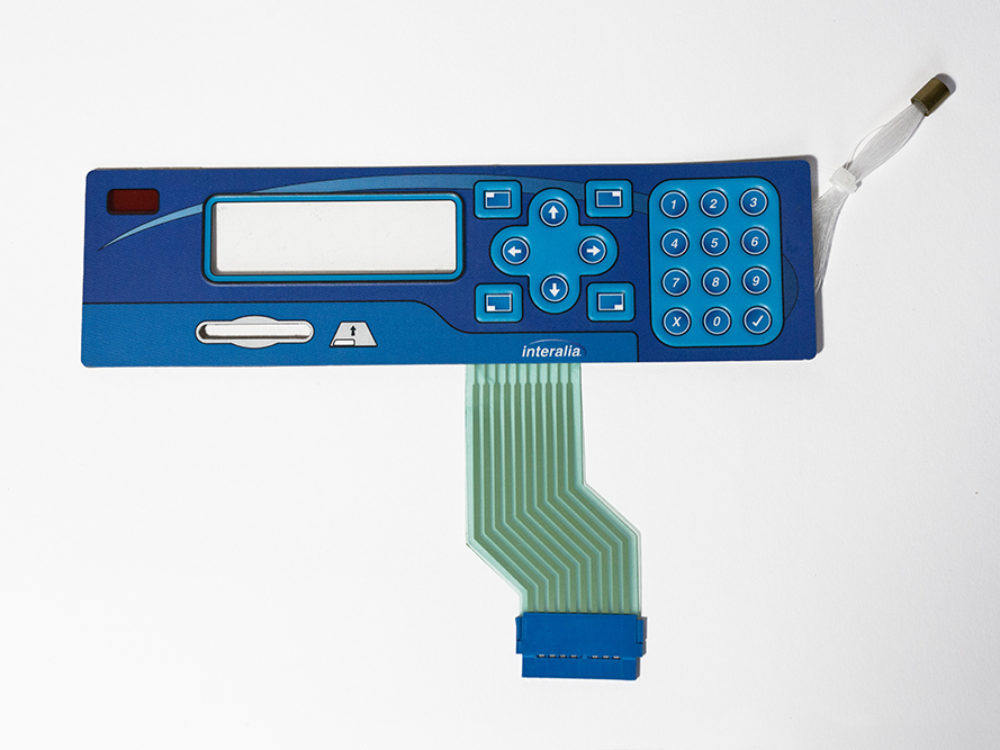

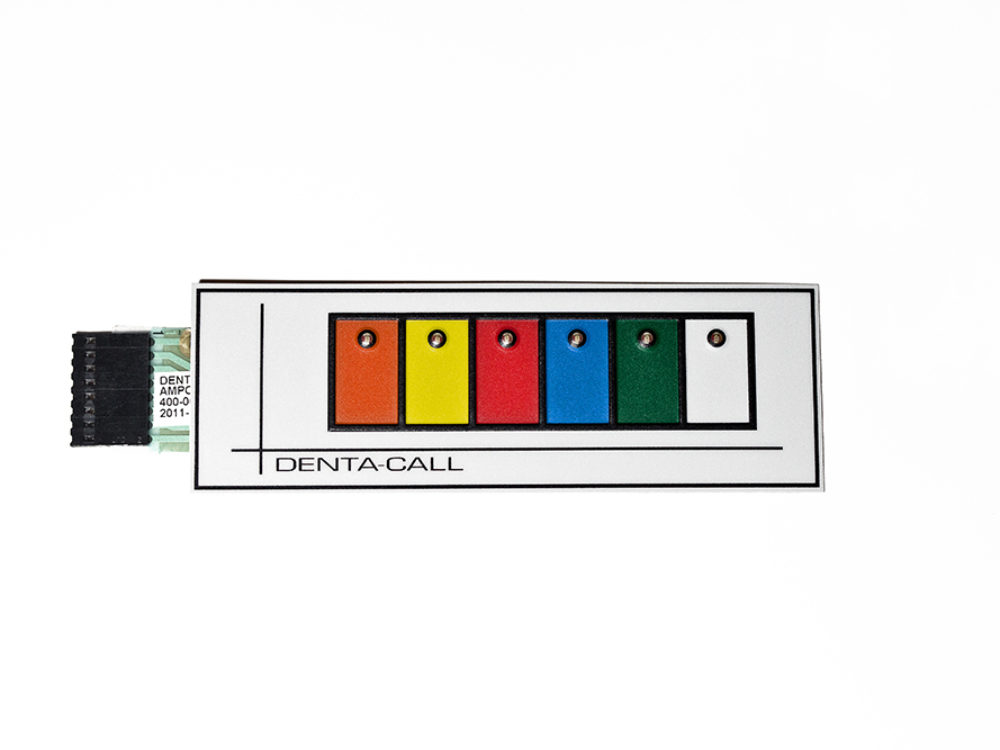

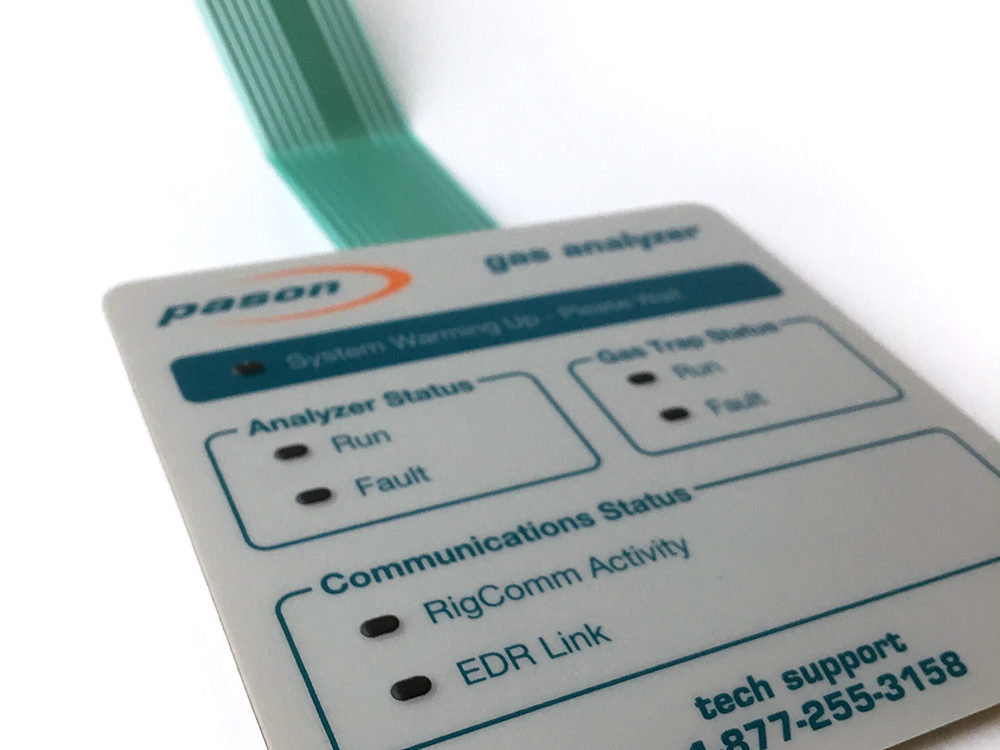

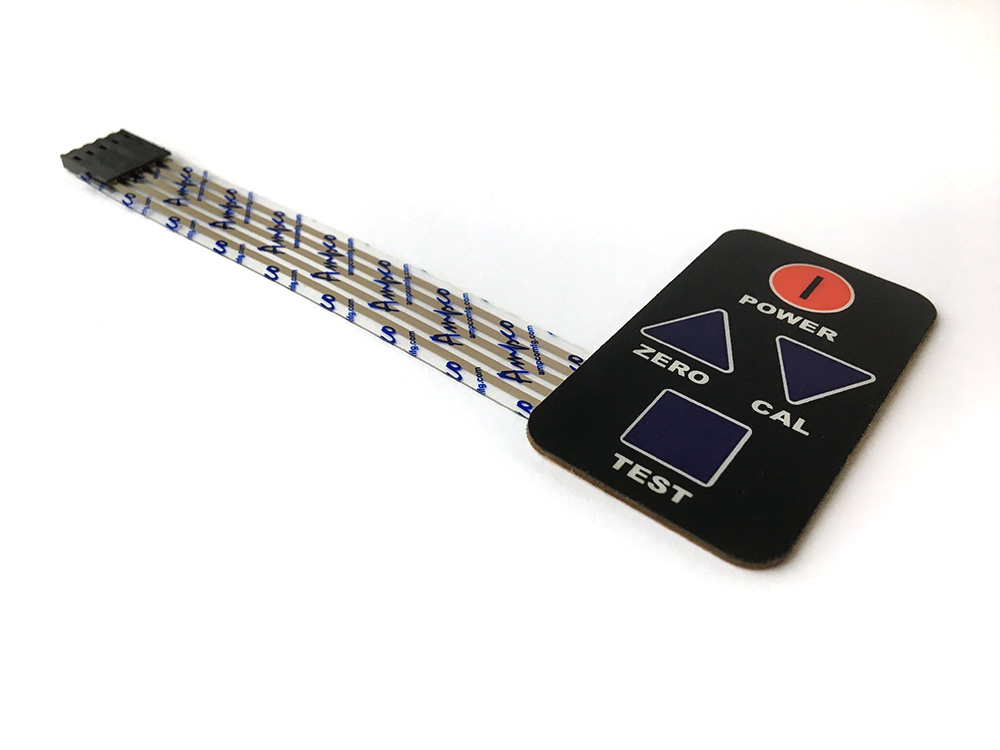

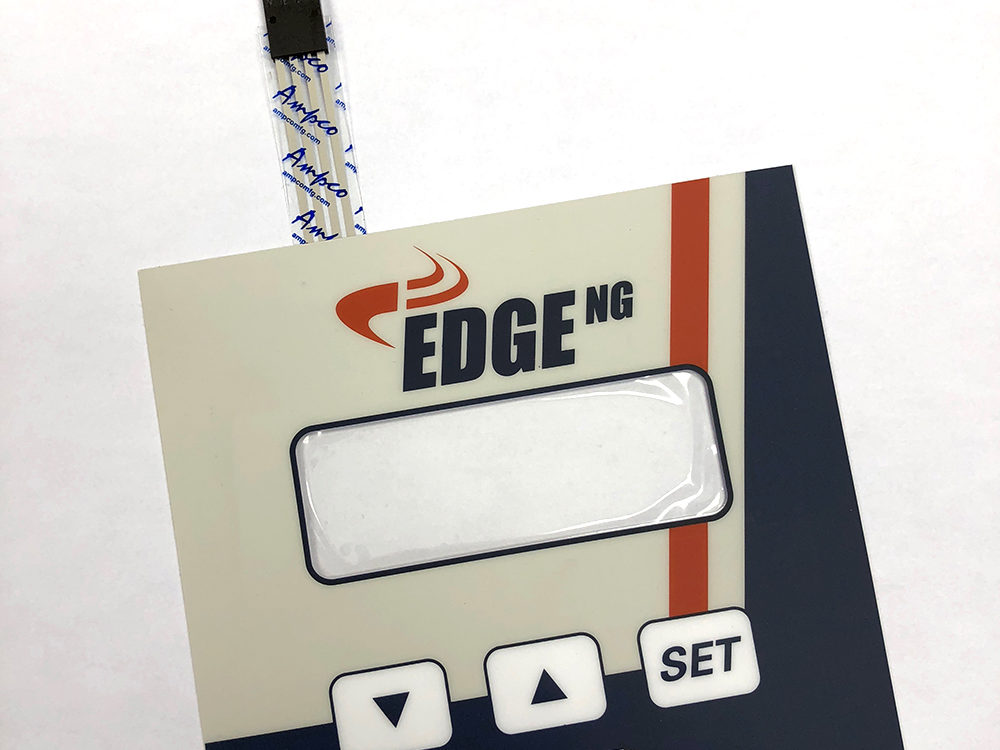

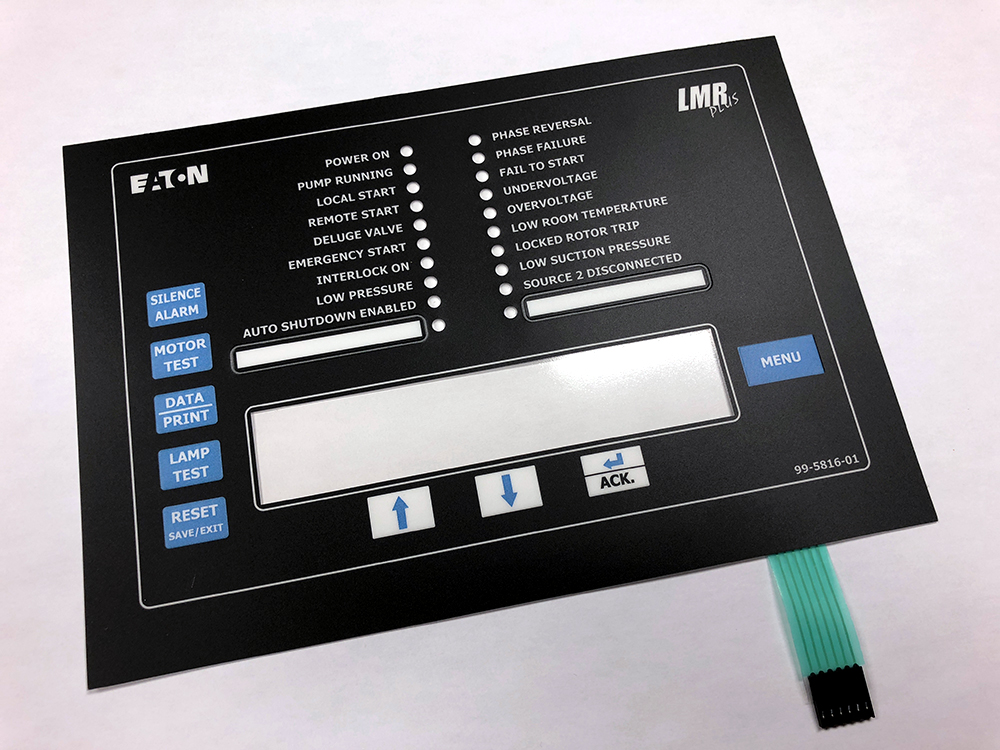

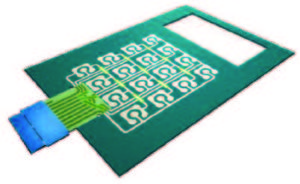

Examples of Custom Printed Membrane Switches by AMPCO

The AMPCO Standard of Innovation

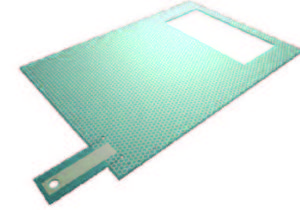

Layers of a Membrane Switch

- Decorated portion of a Membrane Switch representing what the user sees and feels Polycarbonate (LEXAN) or Polyester Materials

- Many finishes available including selective textures/gloss and base materials

- Unlimited colour options including translucent, clear and/or dead-front

- To protect circuitry and electronic components from ESD, EMI, and/or RFI

- Seals provide moisture protection to the switch and the assembly

Ensures tactile domes remain secure and in place

Used only for Non-Tactile Switches

The shorting layer replaces the stainless steel domes/polyester domes or elastomeric keypad

- Used only for Tactile and Elastomeric Switches

- Thickness of the spacer layer defines the tactile response of the switch

- The spacer could include venting for keys or high external pressure changes

- Flexible Polyester or Rigid PCB

- Multi layer and/or double sided circuit

- Printed Silver or plated Copper traces

- Silver circuits are not recommended for soldering

- A variety of connectors and pitches are available to suit your specific design requirements

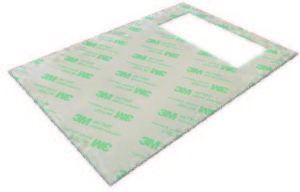

- Most commonly acrylic based pressure sensitive adhesive (PSA)

- Adhesive layer can be customized to best suit the application surface depending on the base surface properties (eg Powder coating)

- Texture of the mounting surface will determine the required adhesive thickness