The AMPCO Standard of Innovation

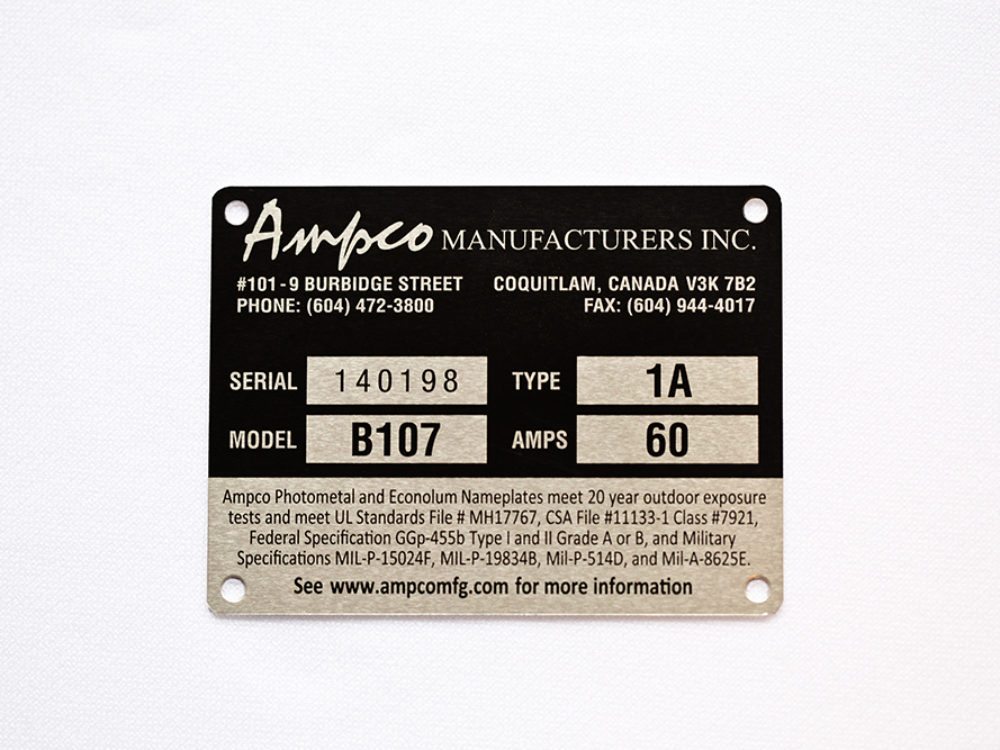

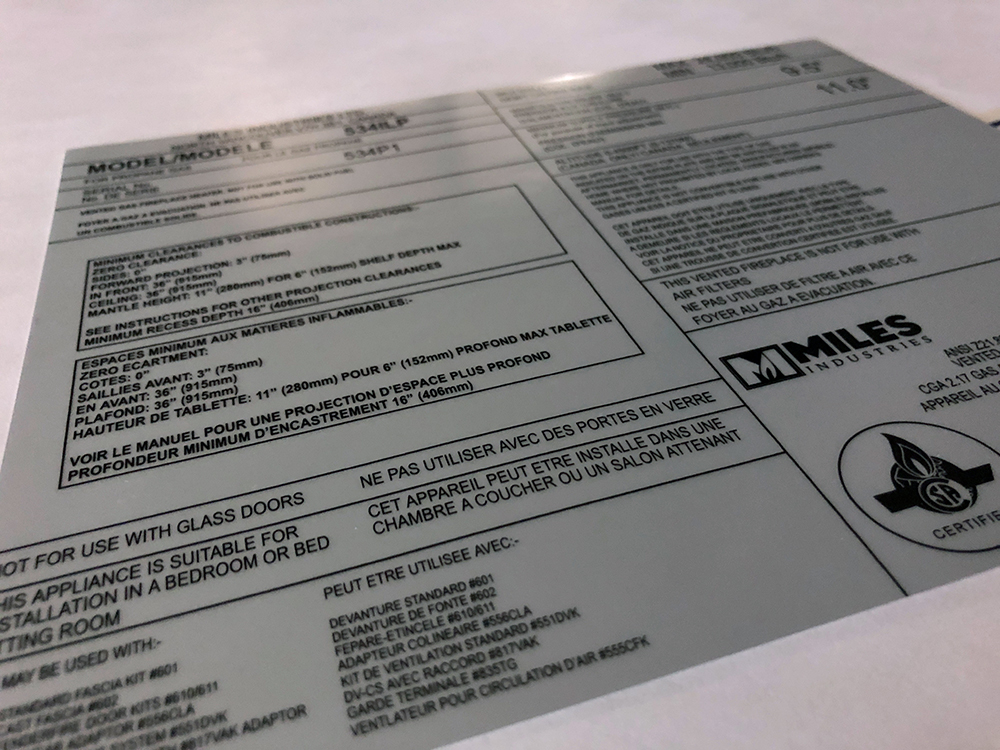

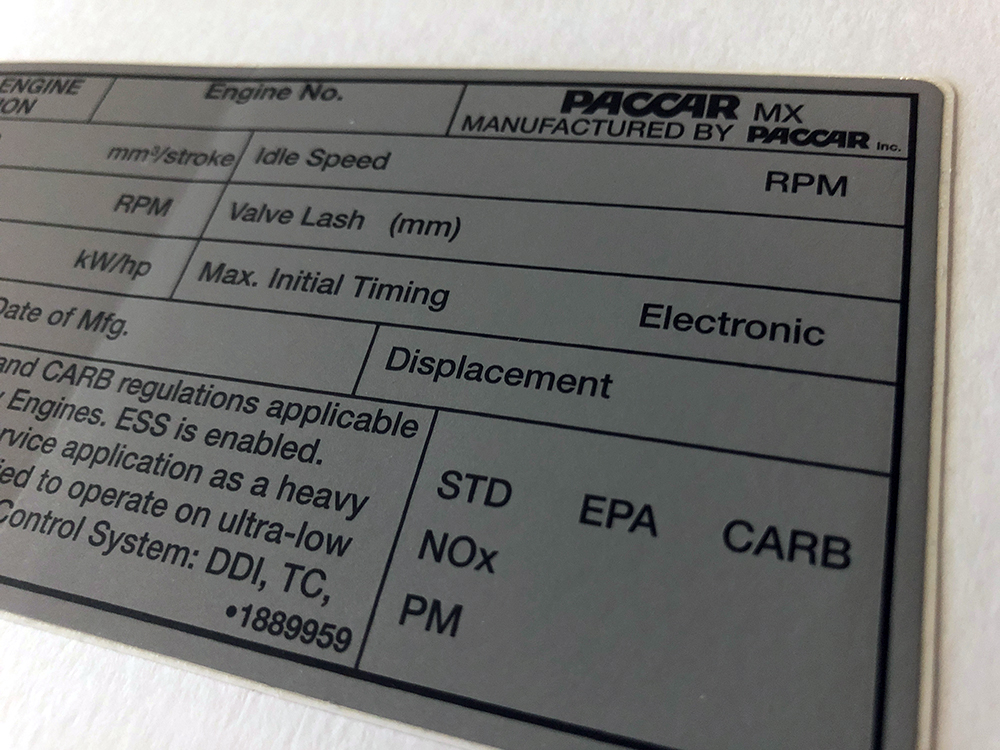

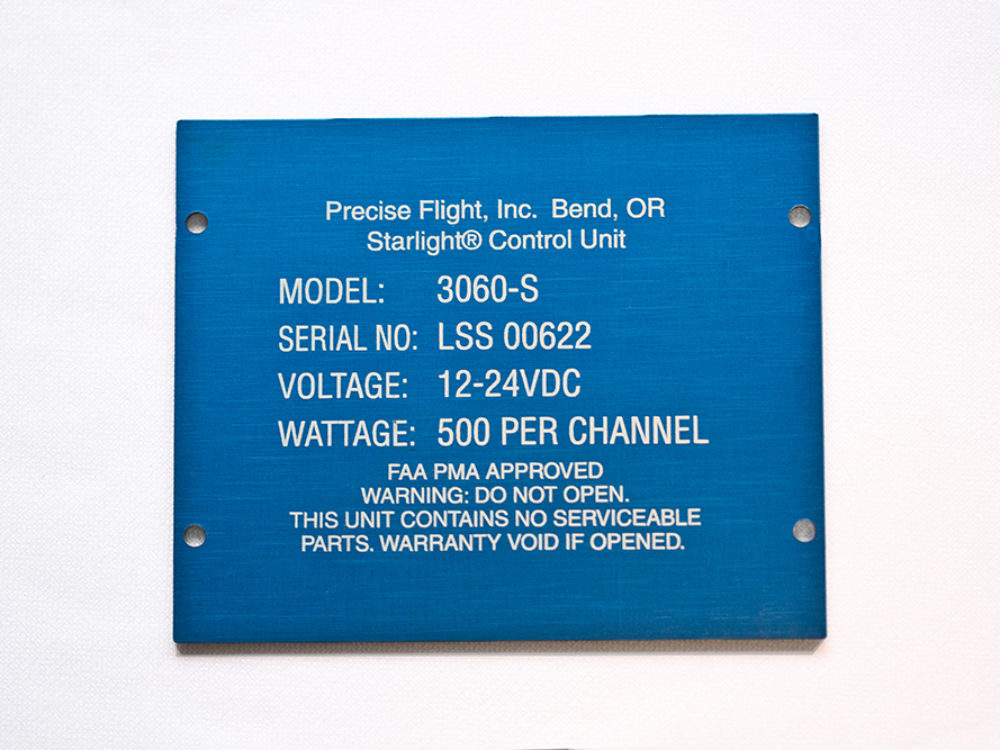

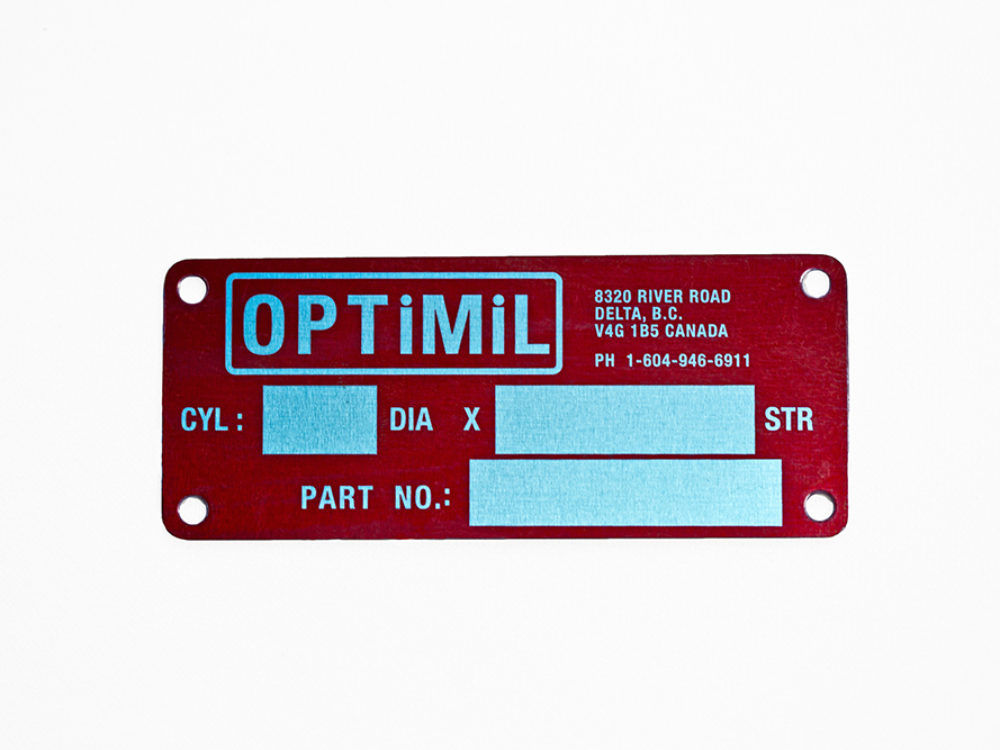

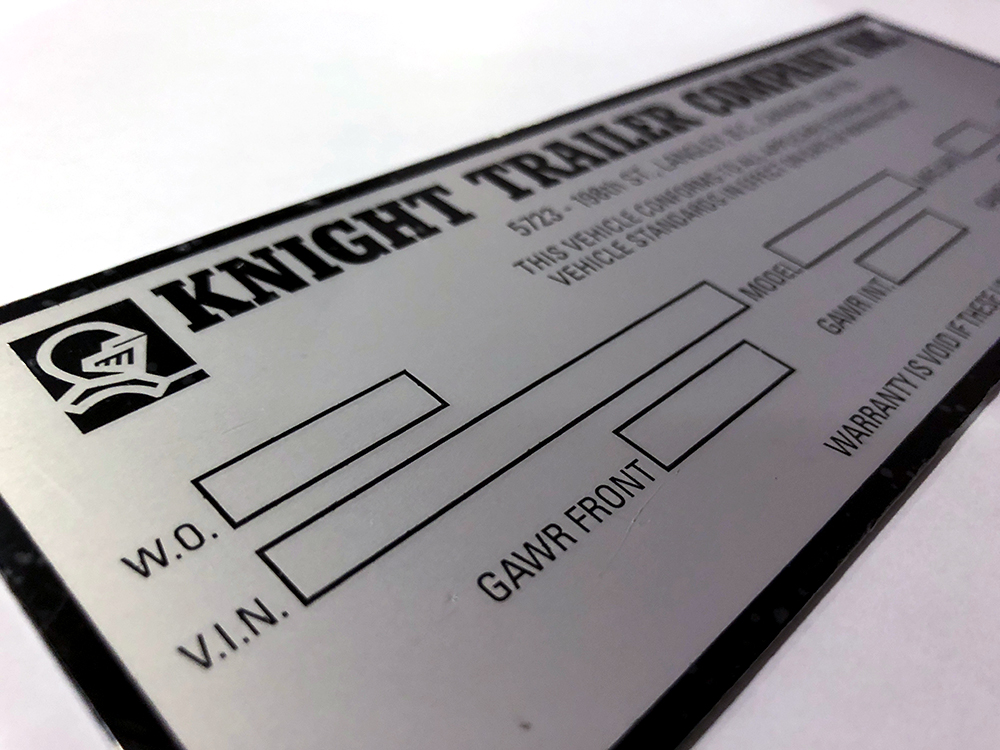

Design engineers in today’s complex world are challenged to develop durable labels, decals and nameplates that will perform as expected in the ever changing world of modern materials. The combination of label material and adhesive play key roles in the durability and performance expectations of these products. At AMPCO Manufacturers Inc. we utilize the latest in print, material and converting technologies to design and produce a diverse line of durable custom decals, labels and nameplates.

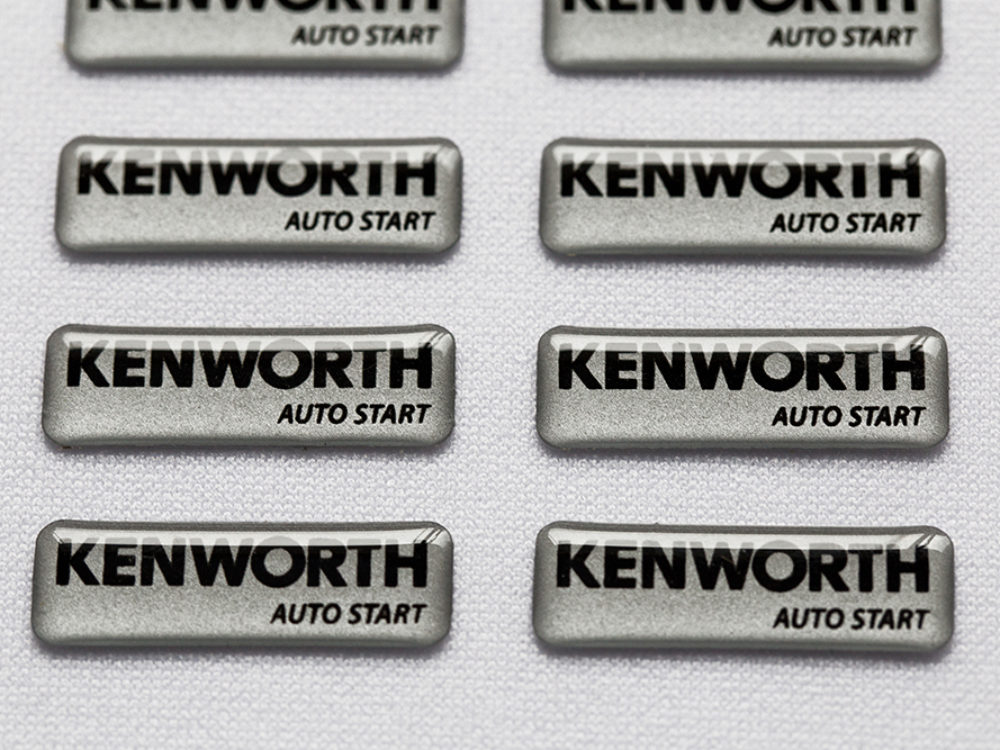

We have expertise in the following custom label, decal and nameplate manufacturing processes: Screen Printing; Digital Printing; Embossing; Die Cutting; Laser Cutting; CNC Cutting; Laminating; Clear and Textured Coatings; Polyurethane Doming; Reflective Materials; Foil and Texturized Products; Photo Sensitive Annodised Aluminium (Perm-A-Plate); Laser Marking; Etched and Filled.

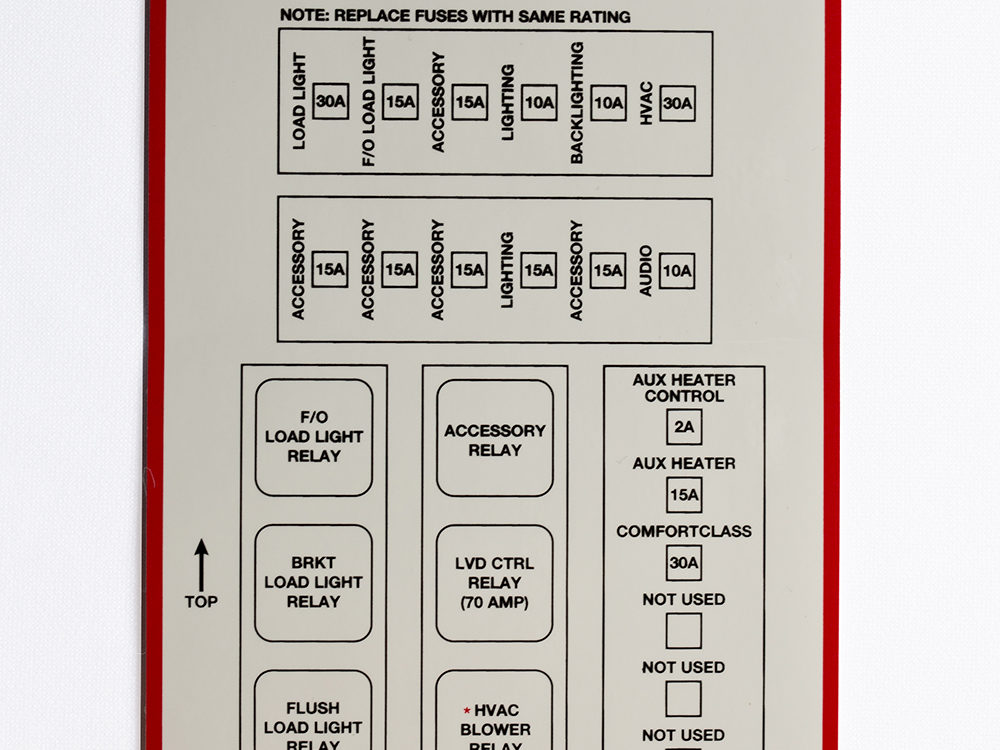

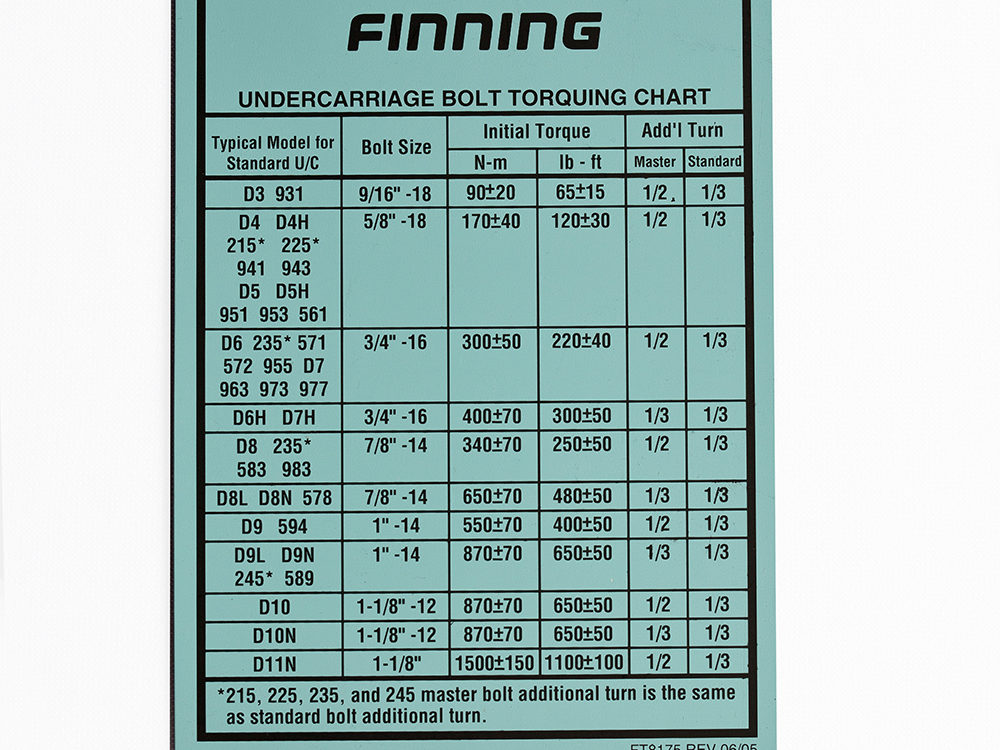

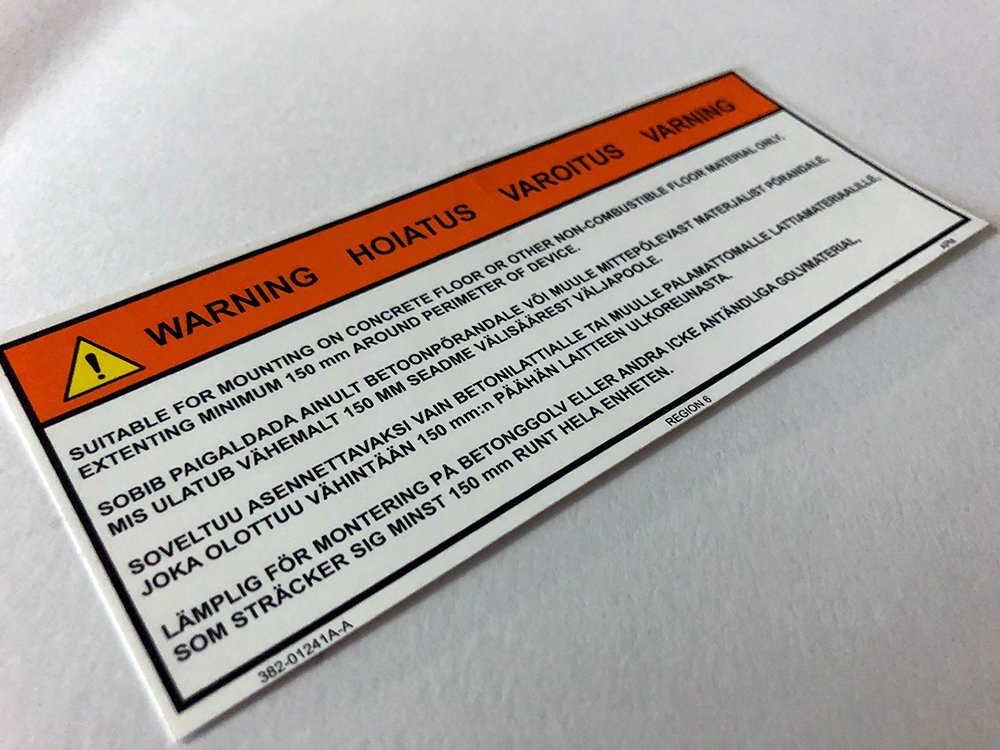

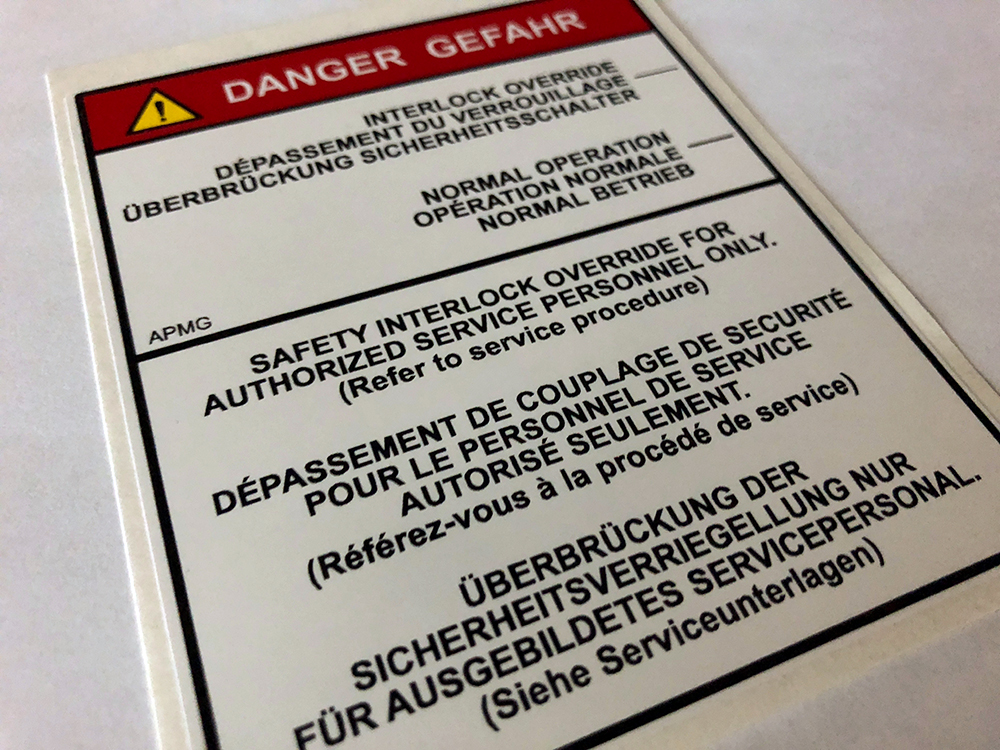

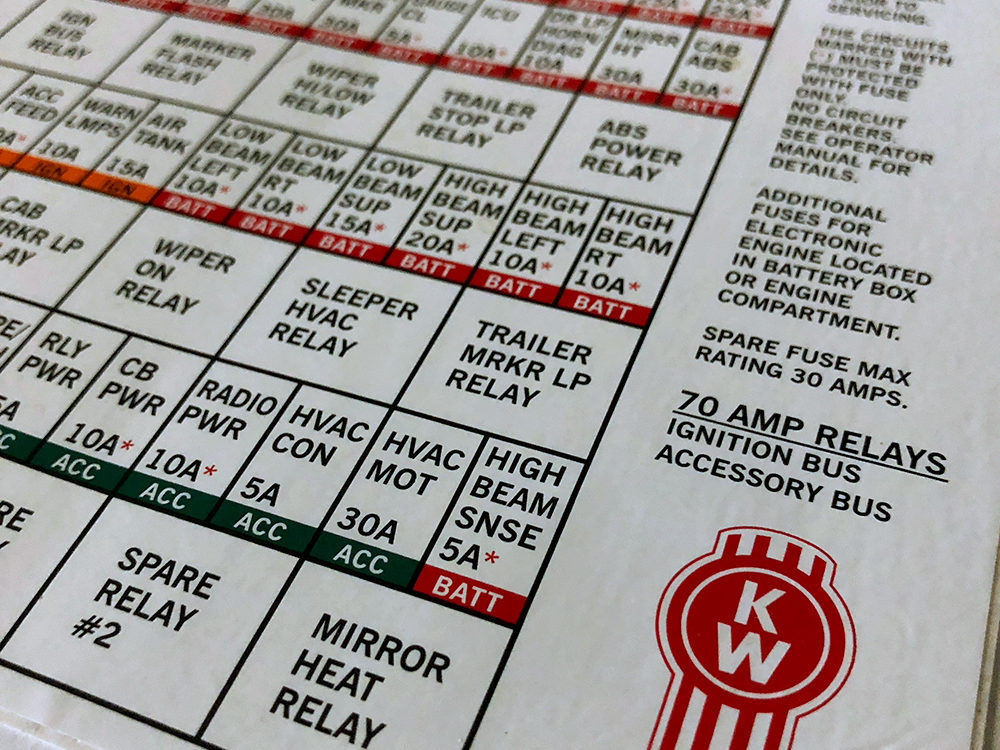

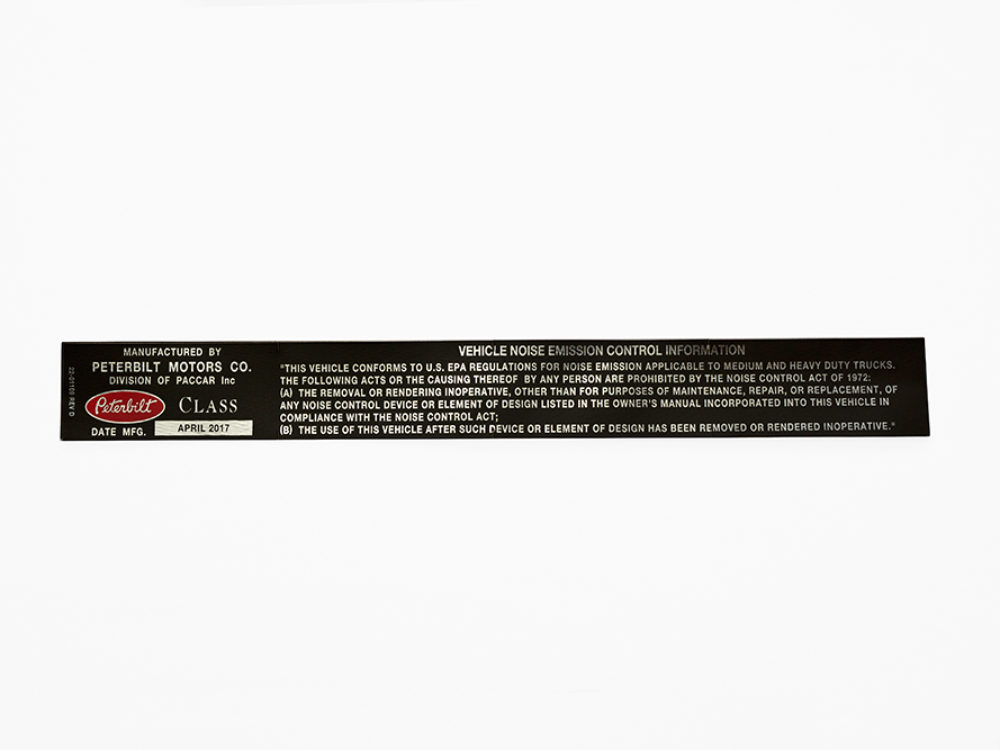

We specialize and are able to supply: Agency & Certification Labels (UL, cUL, CSA & CE); Safety & Instructional Decals (Ansi; Harzardous Materials), Product Identification Decals; Serial Number/Bar Code Labels, Flexo/Roll Labels; Label Kits; Tamper Evident Labels and Inventory Management Programs.

Utilize the Expertise and Experience of AMPCO to review your durable decal costs today!

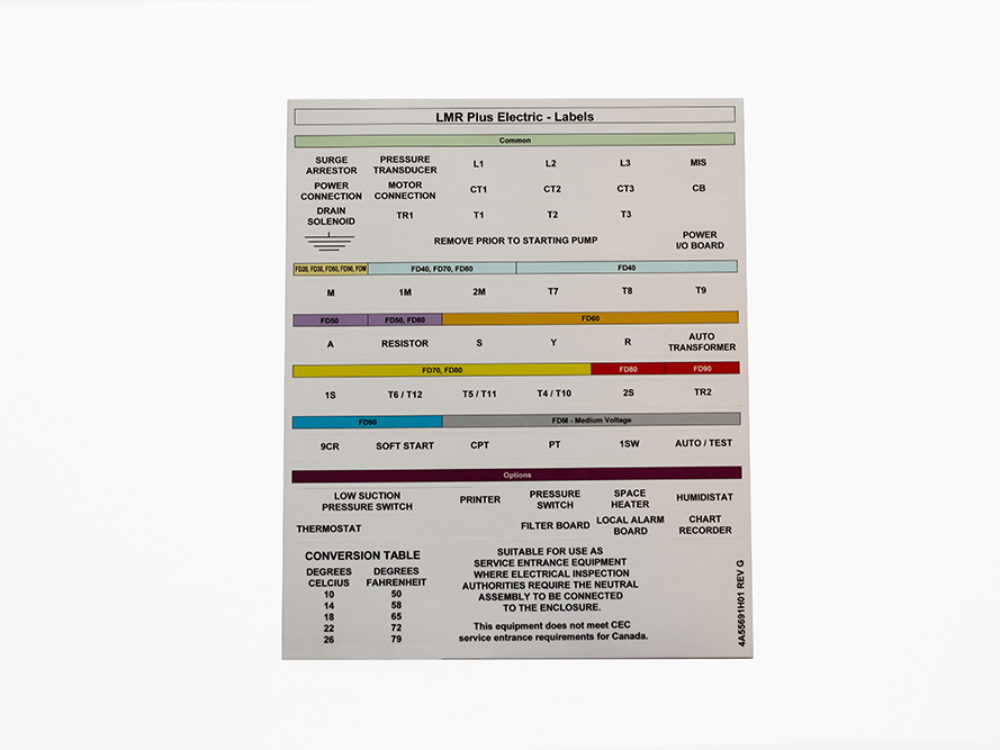

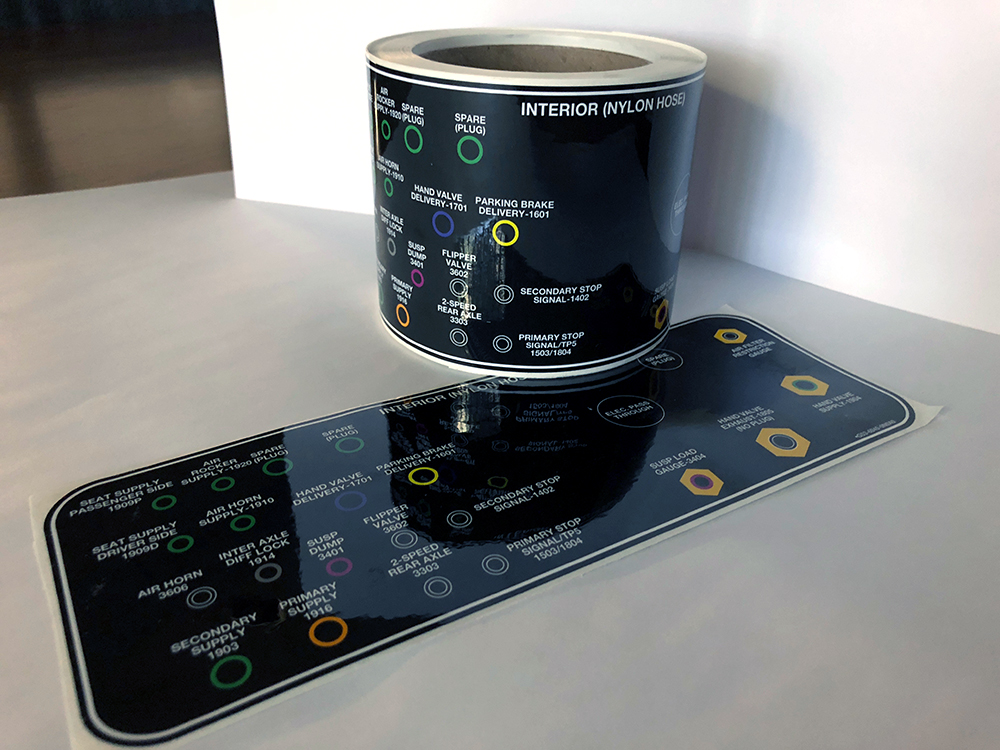

AMPCO designs and develops custom label kits as a way to maximize efficiency and reduce cost on low volume labels by producing them in kit form.

We take advantage of the combined volume to drive costs down and pass on these savings.

This allows us to standardize material, colours and application methods to streamline your production flow and provide consistent products our customers expect.