The AMPCO Standard of Experience

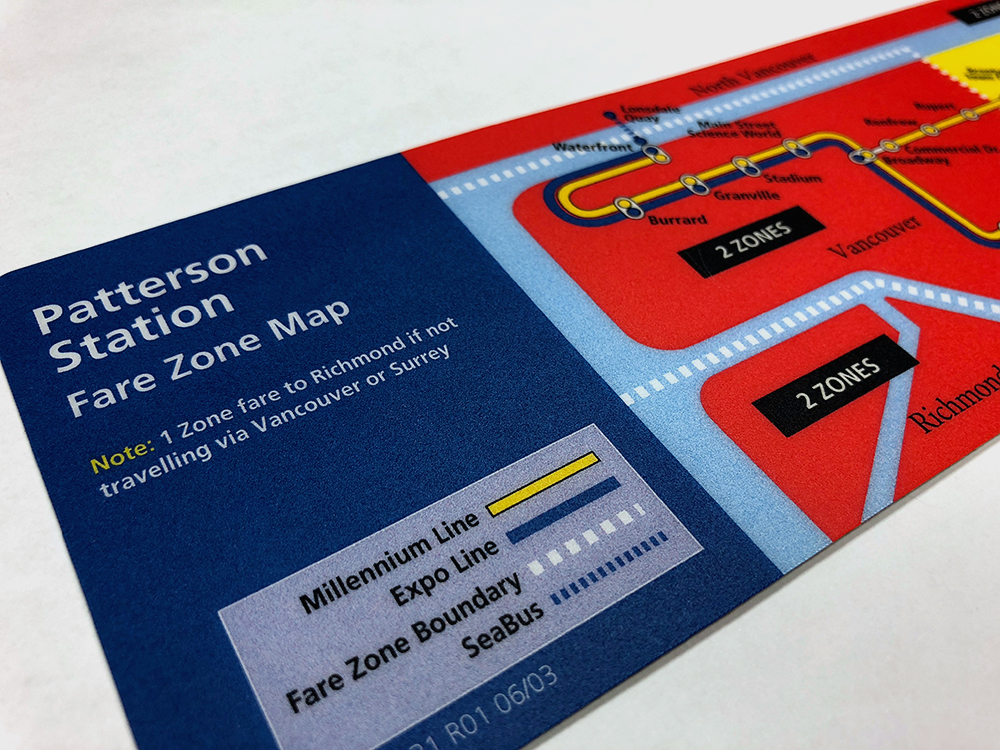

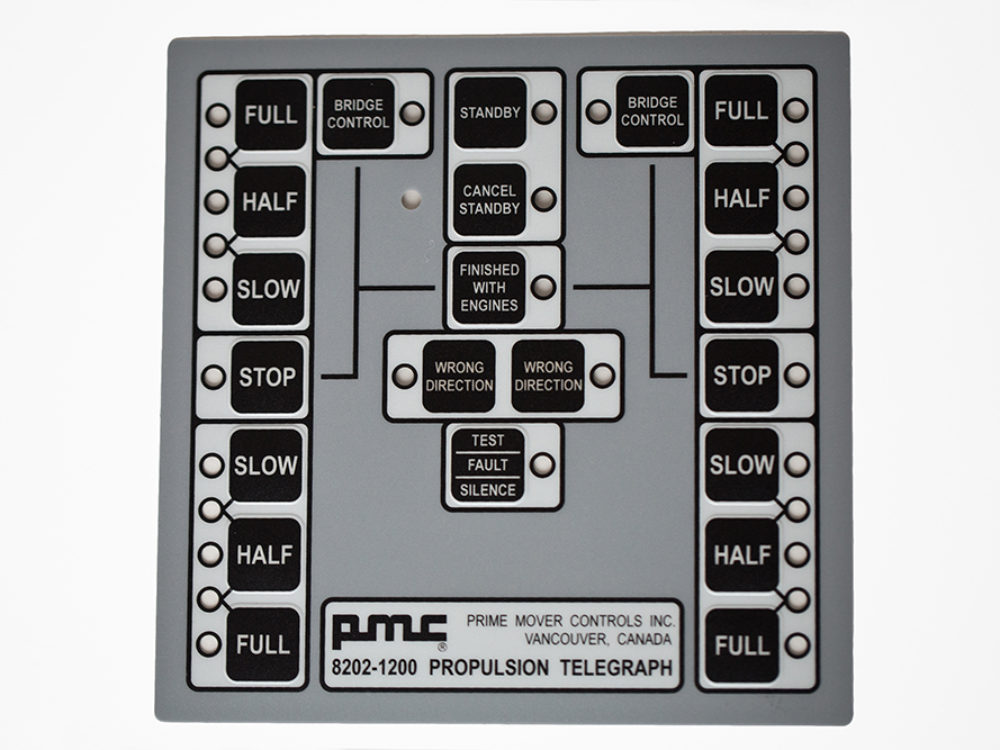

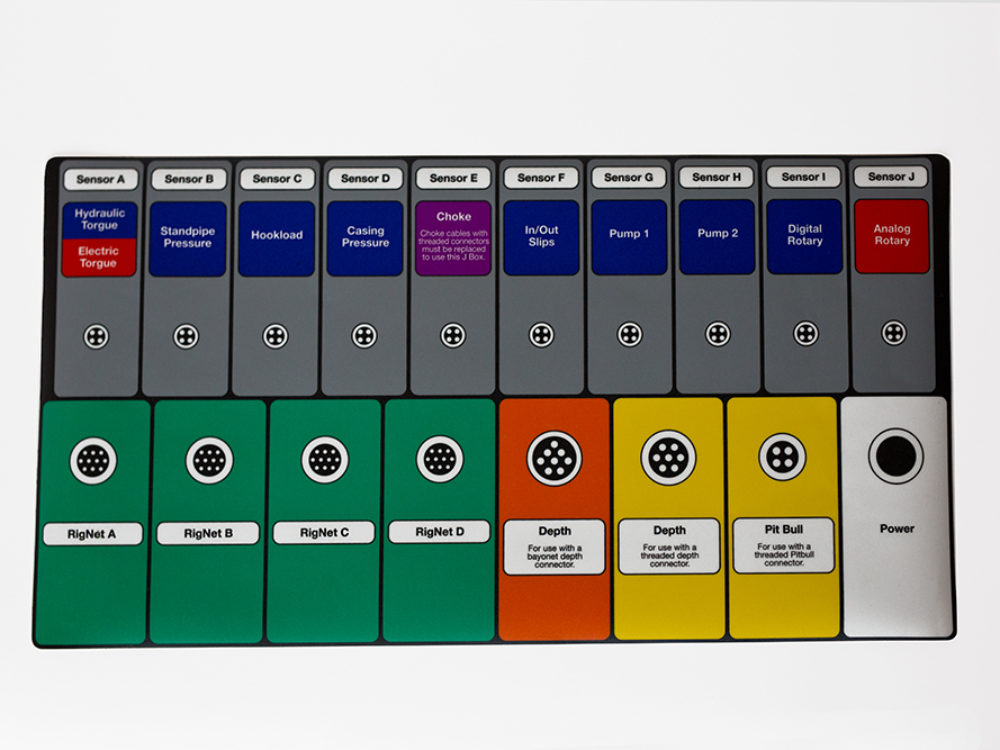

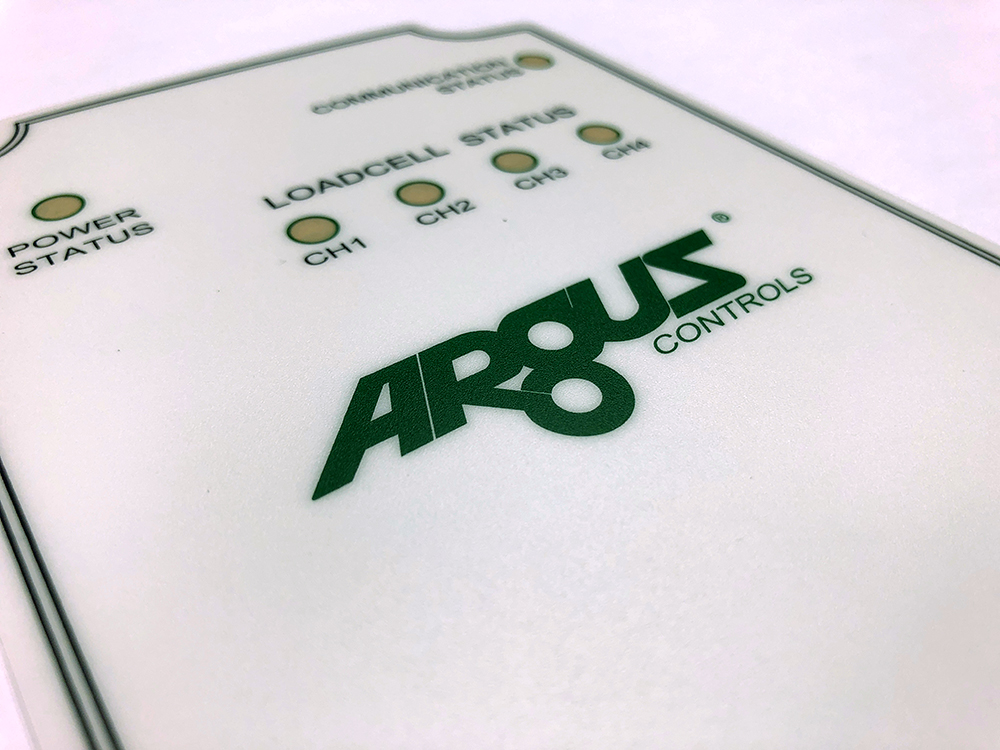

Providing high resolution, picture quality graphic overlay printing and manufacturing.

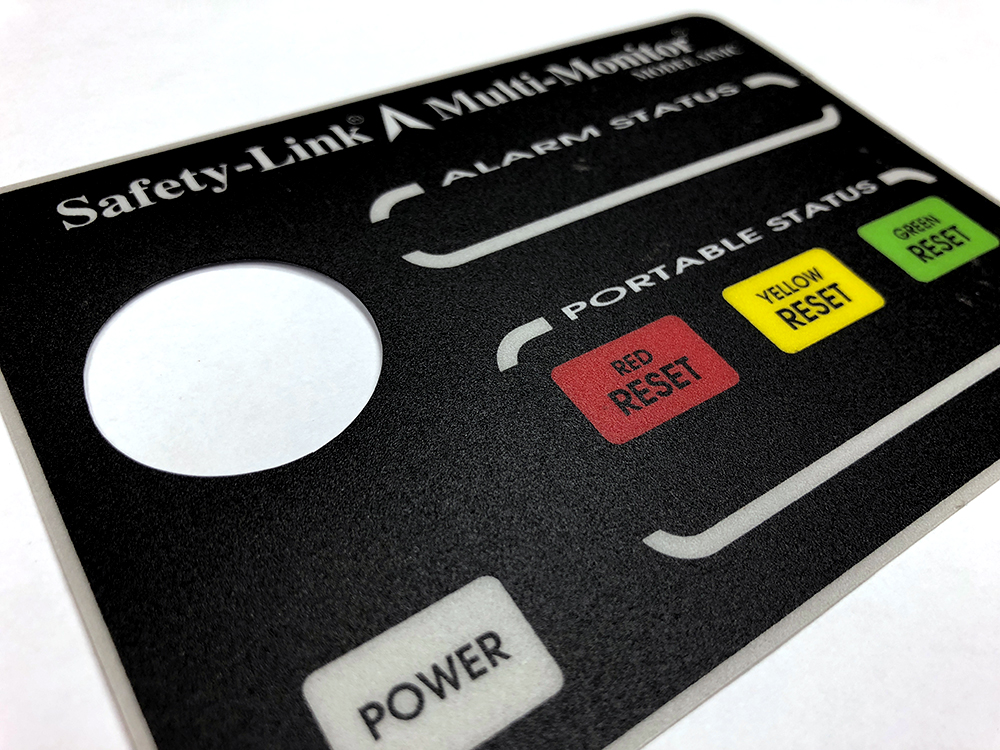

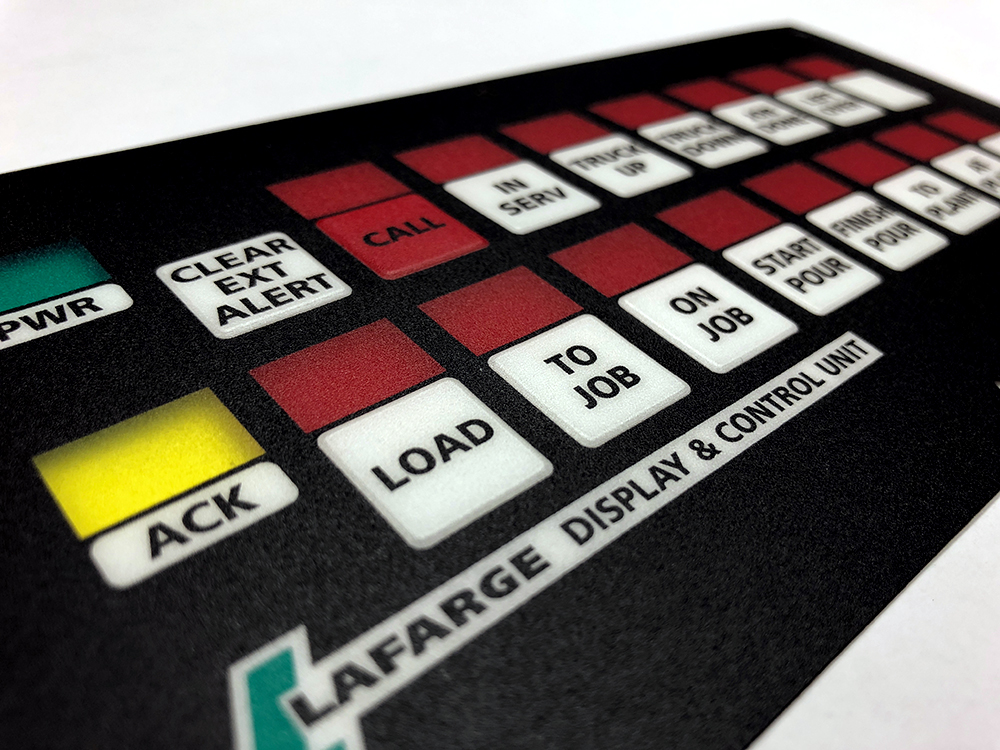

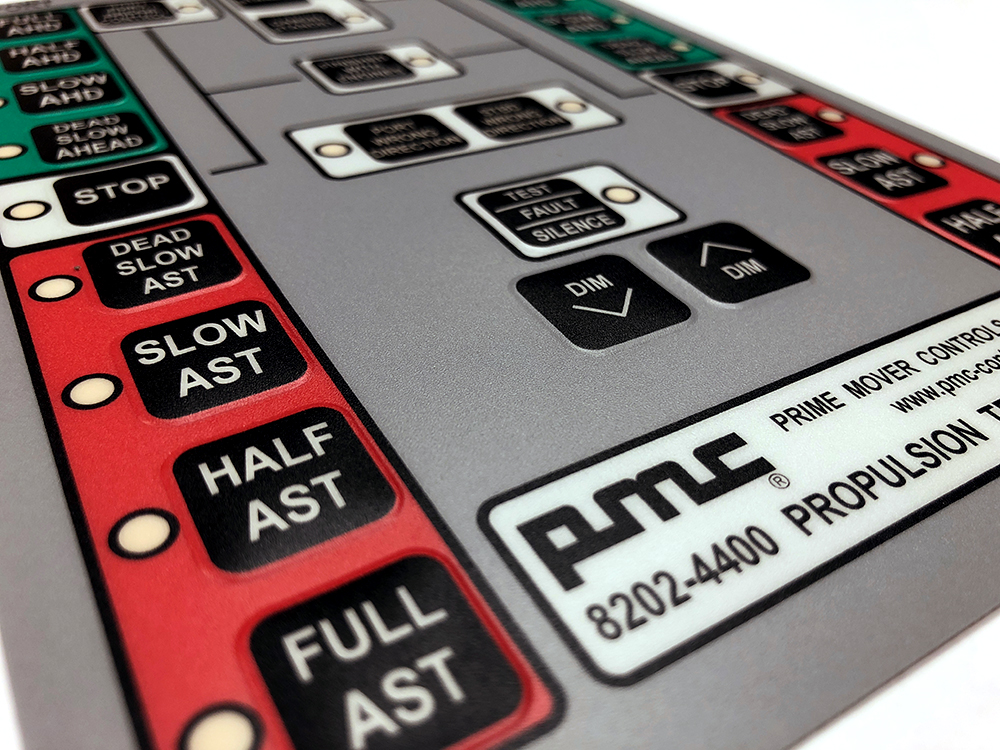

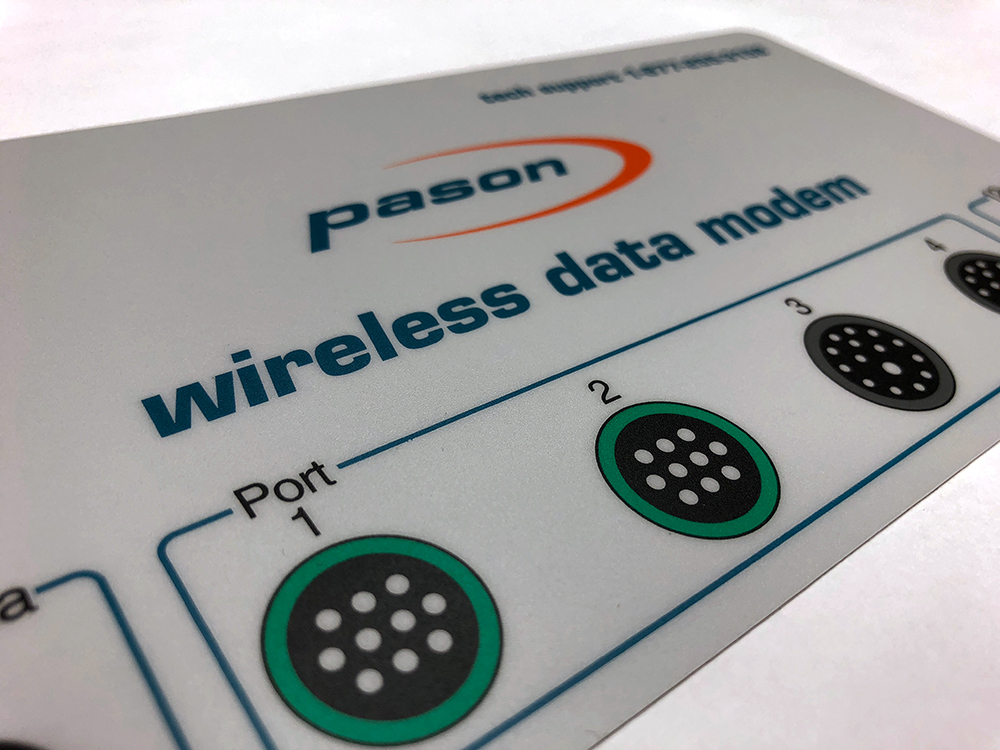

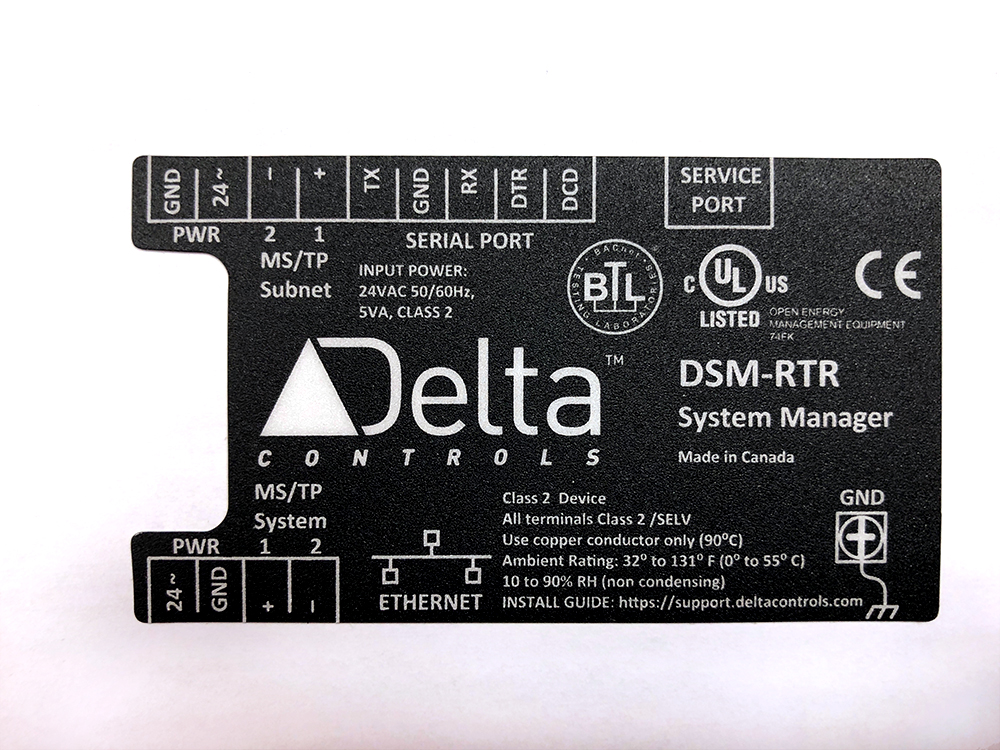

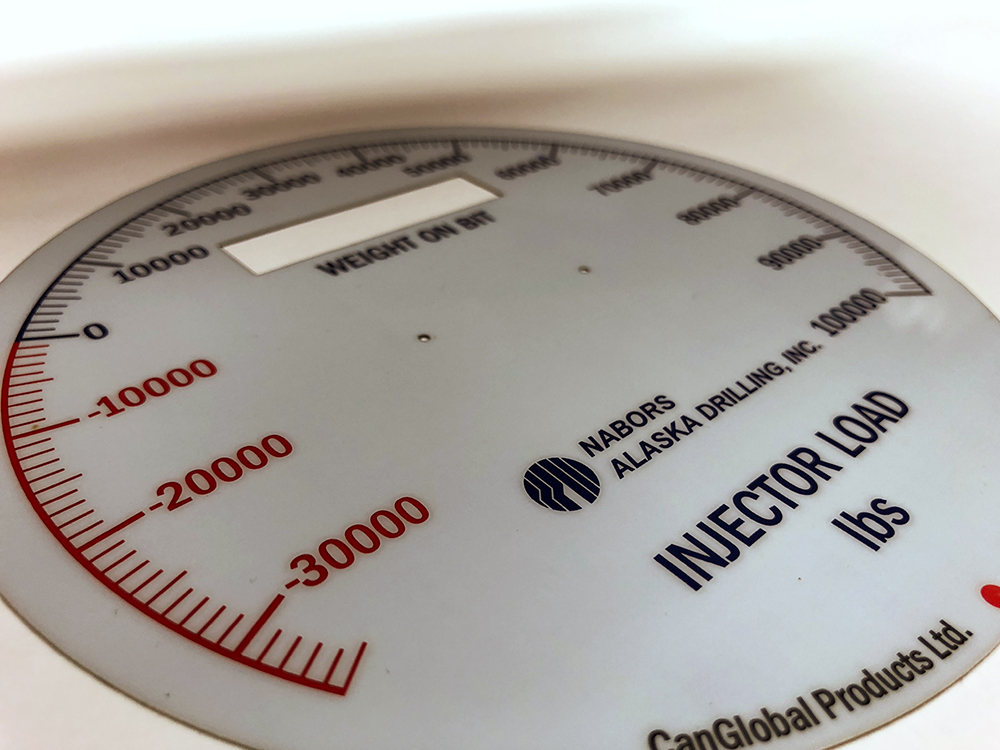

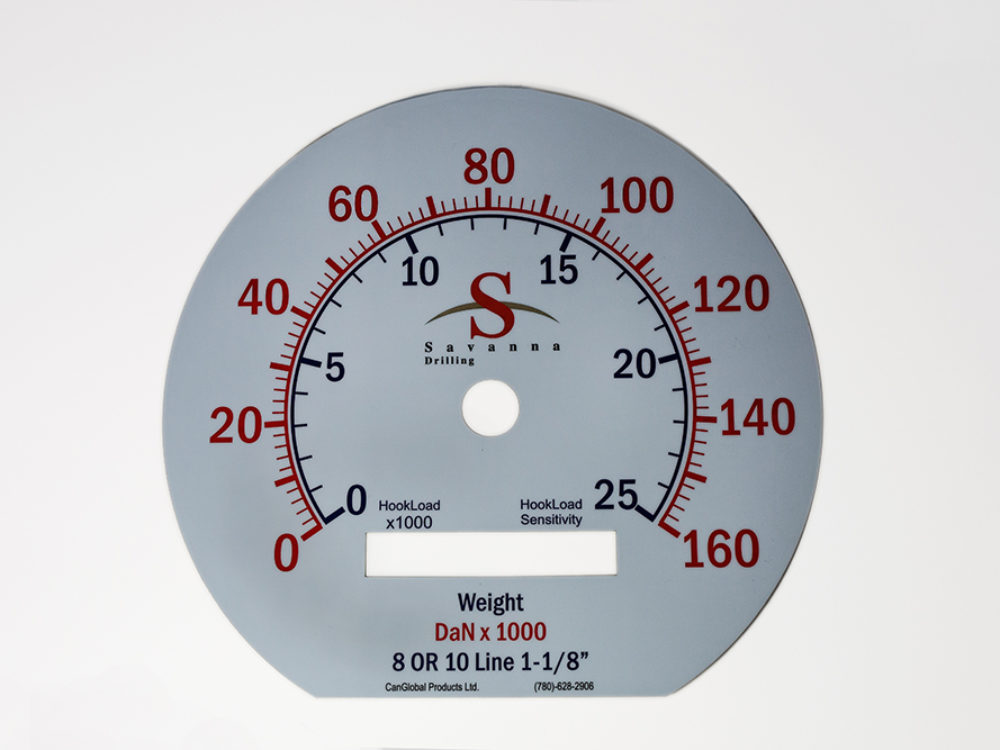

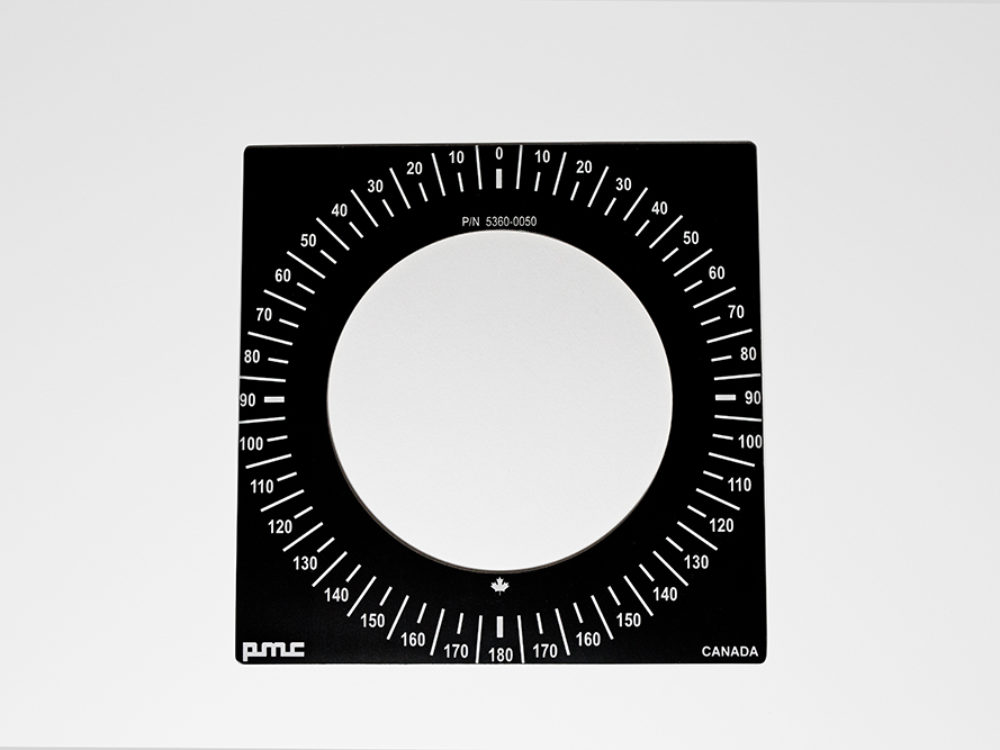

As the interface between user and machine, it is the graphic overlay that will directly impress your customer when placed on the surface of a product.

Design engineers request overlays in a variety of materials, most often Lexan polycarbonates or hard coded polyesters that meet the performance needs while providing the high end look and appeal.

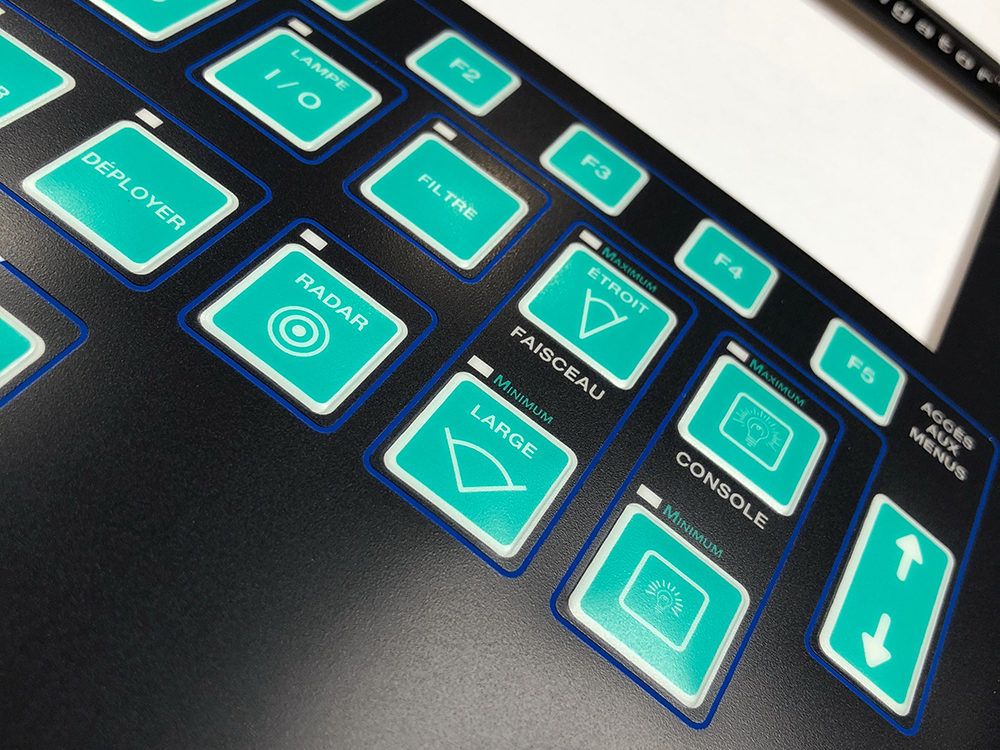

Backlighting:

Ampco’s Engineers can also design custom waring lights and an array of backlit panel assemblies to suit your unique needs. Our converting capabilities include clamshell press, four post thermal press, CO2 laser cutting; CNC cutting; Plotter cutter.

Our Capabilities Include:

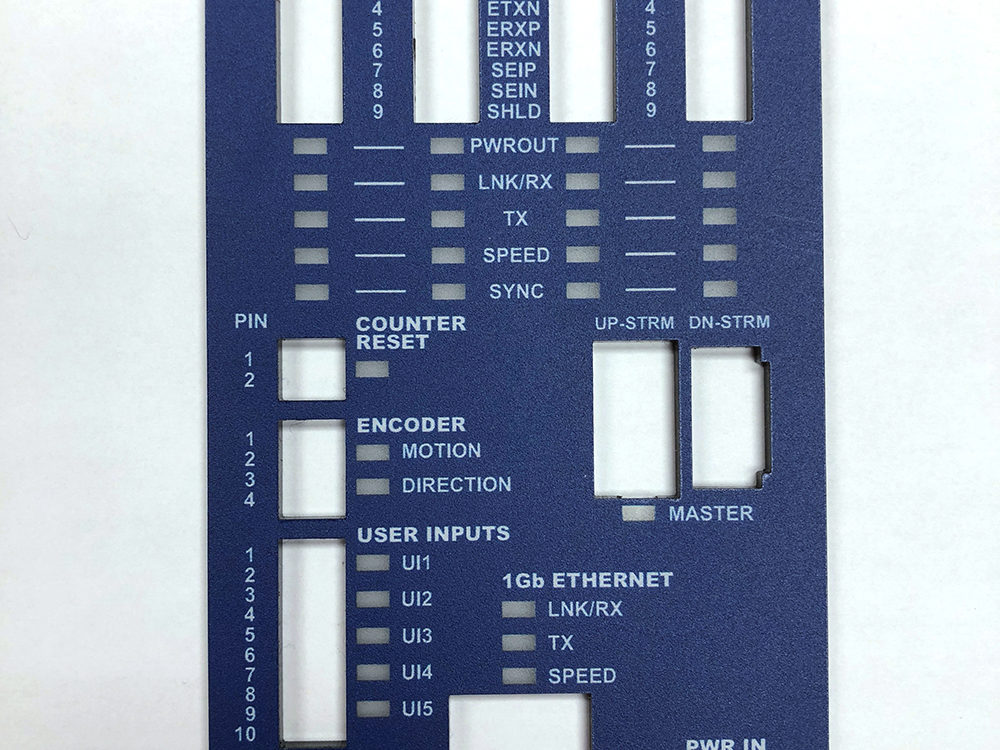

Multiple colours and colour matching; Translucent and opaque printing; digital and screen printing; Variable data and micro printing; embossing with rail, pillow or dome; material and adhesive selection; selective texture and gloss; window can be clear, tinted or translucent.

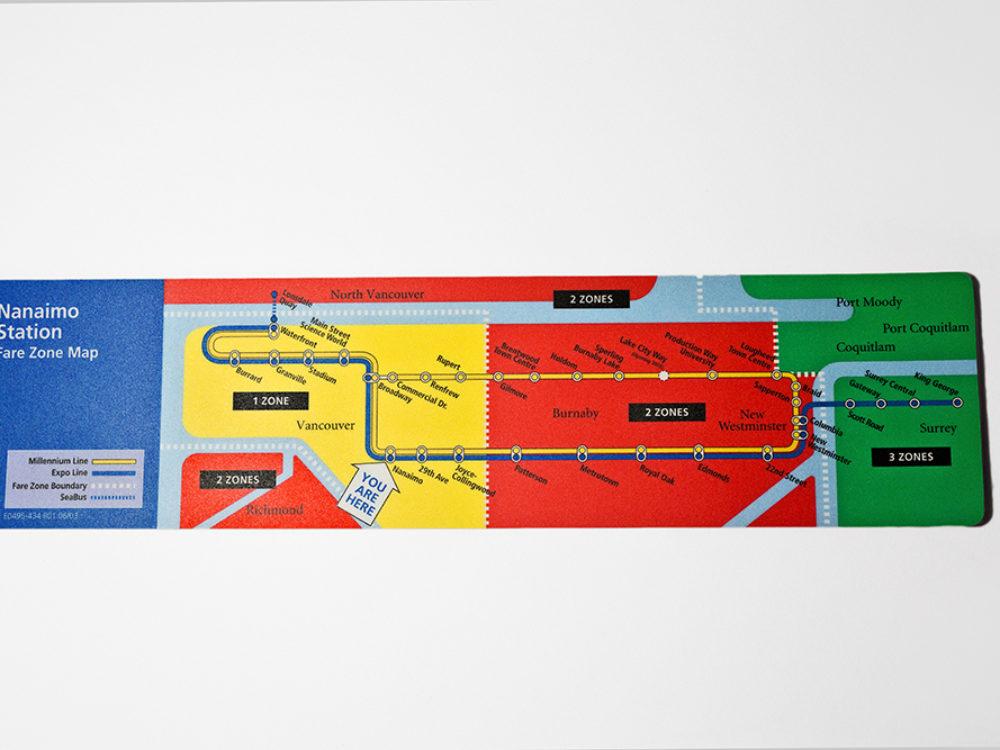

BLUE SEA SYSTEMS – Why Overlays can be complex…

“Blue Sea Systems have worked with the AMPCO team since 2005. They provide graphic overlays for the Blue Sea Systems marine electrical products that are subject to a harsh salt water environment. The labels are scratch proof, back-printed for durability with waterproof adhesive for permanent placement. Specific ink blends that remain consistent to a master colour swatch over many years.

The die cuts have concise tolerances in order to fit perfectly into the label recesses of the products. Form and fit have been very precise over the years. Orders are consistently received by due date, sometimes with very short turn around requests. AMPCO is located in Canada but easy to work with from the USA. The company is willing to work to provide the best possible value often suggesting options that decrease cost and increase efficiency. It’s the people that make the success.”